Exploring different generative slicing methods to improve the 3D printed elements' structural proper

This project aims to explore the impacts of slicing algorithms on the quality of extrusion based 3D prints and develop generative slicing algorithm(s) to improve printability and/or structural performance.

Introduction

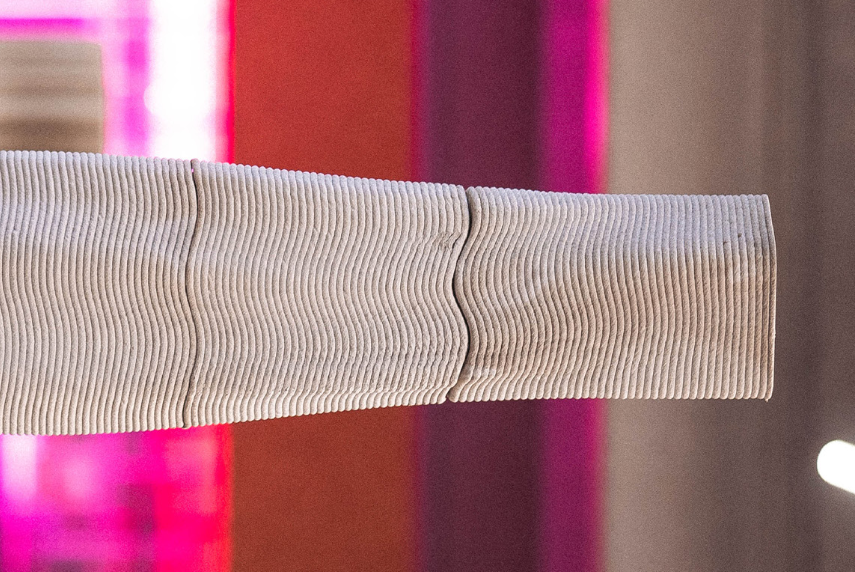

Extrusion based 3D printing uses a nozzle to place the filament on a given path. Typically, this path is generated by slicing algorithm that cuts the desired geometry into contours with a series of XY planes offsetted by the layer height. This method of slicing results in geometrical limitations, particularly when it comes to overhangs or cantilevers. In literature there are examples of different slicing algorithms enabling more complex shapes to be printed. It is also unclear how slicing techniques influence the structural performance of the print, or how different materials choice could limit the slicing options

Source: M. Ferguson, “A Digital Workflow for the Design and Manufacturing of 3D Printed Concrete Bridges in a Circular Economy:,” Technische Universiteit Eindhoven, 2022.

Method

The project will start with an initial literature review on existing slicing algorithms used for different materials. Different geometries with different challenges will be designed to test the existing slicing algorithms and create new ones. Depending on the direction of the research, the influence of slicing will be tested and improved and the effects of the new algorithm will be measured. After this iterative phase on a selection of geometries, the algorithm will be further developed to be generative to be applicable to different geometries.

Requirements

We are looking for curious students who are interested in digital fabrication and computational design. It could be advantageous but not required to have some experience with coding in python, C# or similar. We are hoping to achieve results that can be published in a conference or journal paper. The project will be supervised by Idil Gumruk and Rob Wolfs (SED). For more information on the project, do not hesitate to contact Idil Gumruk i.gumruk@tue.nl.