Design of a novel 3DPC mixture using local clay materials

In this project you will be working on the design of novel low-carbon mixtures suitable for 3D printing purposes using local clay materials.

Despite the numerous advantages and benefits of the technique, sustainability is one of the key issues which is still lacking in 3D concrete printing. As 3DPC contains a 2 - 3x higher cement content compared to traditional concretes, there is a huge challenge in finding ways to reduce the CO¬2 footprint of the material.

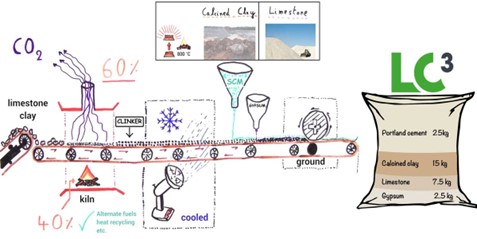

In this project you will be working on the design of novel low-carbon mixtures suitable for 3D printing purposes, using local clay materials. Clays can be found everywhere, especially in the soil around us. When calcining these clays, they can have great potential in (partial) cement replacement in 3DPC. The reactivity of the mixture, however, depends amongst all on the type of clay used. This project focusses on the use of local clay materials as cement replacement in 3DPC. To what extent can local, Dutch clays, contribute to creating sustainable 3DPC mixtures? And how can these clays be applied using activation techniques such as calcination, mechano-chemical activation or LC3?

Source: LC3 cement can reduce carbon emission by 40% (constructionworld.in)