Digital Twin for fatigue of an offshore monopile structure

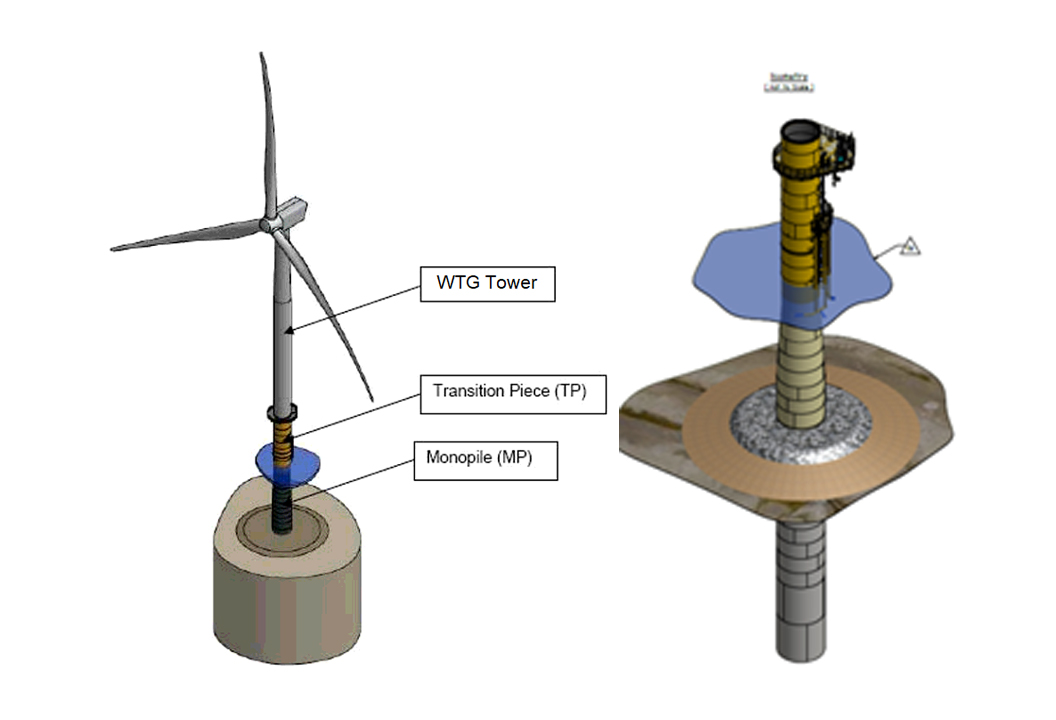

This project will look at the residual fatigue life estimation of circumferential welds located along the monopile and above the mud-line within a structural health monitoring framework.

Introduction

The offshore wind market is developing at an incredible pace. Wind turbines are increasing in size and the end is not yet near. Larger turbines mean higher loads and larger foundations. Understanding the condition of the monopile structure, together with the condition of the turbine drive system, is very valuable for wind farm owners. In particular, this project will look at the residual fatigue life estimation of circumferential welds located along the monopile and above the mud-line within a structural health monitoring framework.

The study aims at performing a realistic fatigue life estimation of the monopile structure using operational service loads recorded by a monitoring system. Accurate fatigue life prediction allows safe use of a structure, at the same time maximizing the availability of the asset. This results in possible lifetime extensions that will bring economic and ecological benefits.

Goal

The goal of this project is to develop a prognostic tool for fatigue of welds located along the monopile structures to be employed into a Structural Health Monitoring framework. Based on existing modeling strategies, finite element models will be developed to relate the output of the structural health monitoring system (e.g. strain, acceleration, and metocean data) to internal forces acting along the monopile. Moreover, the model is used to develop a digital twin for real-time monitoring. The methodology will encompass the development of algorithms and scripts to translate strain, acceleration, and metocean data into fatigue conditions of the welds, and predicting the remaining useful life.

Plan

The project will comprise the following:

o Literature study

o Developing the methodology

o Case study for a steel monopile foundation structure. At HVR Engineering, the company involved in this project, some data is available. More data may be retrieved via industry partners (customers of HVR Engineering).

Experimental vs. numerical comparison for optimization of methodology.

Supervision

The project will be supervised by Prof. Bert Snijder, Davide Leonetti from TU/e and Michele Orlando from HVR Engineering

For more information, please contact Davide Leonetti.

Useful References

Velarde, J., Kramhøft, C., Sørensen, J. D., & Zorzi, G. (2020). Fatigue reliability of large monopiles for offshore wind turbines. International Journal of Fatigue, 134, 105487.

Biswal, R., & Mehmanparast, A. (2019). Fatigue damage analysis of offshore wind turbine monopile weldments. Procedia Structural Integrity, 17, 643-650.