Fatigue design of thickness transitions

Rijkswaterstaat is looking for a master thesis student to fill knowledge gaps related to thickness transitions in bridge girders.

Rijkswaterstaat is looking for a master thesis student to fill knowledge gaps related to thickness transitions in bridge girders. Your contribution to the literature will require the use of finite-element analysis software (e.g. Abaqus) and of your analytical skills. There is a possibility to carry out tests for validation purposes. The findings of your work contribute to the assessment of both existing and new bridges within the network of Rijkswaterstaat.

More information:

- Johan Maljaars, j.maljaars@tue.nl

- Martin Nijgh, martin.nijgh@rws.nl

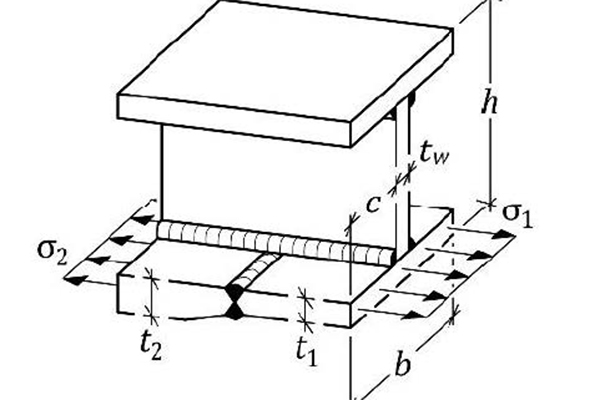

Thickness transitions in plate elements (for example beam flanges) contribute to the optimal use of steel in welded (built-up) girders. Thickness transitions are applied in many steel (and aluminium) bridges. The flange thickness increases in regions with larger bending moments and decreases in regions with smaller bending moments.

The change of the cross-section of the girder causes complex local stress fields that classic beam theory cannot capture. The eccentricity of the flange plates causes a bending moment in the flange. The resulting stresses in the flange plates vary along the width of the girder: at the plate edges there is mostly unrestrained bending, whereas closer to the web the bending is more or less restrained.

Fatigue plays an important role for bridge girders. The thickness transitions in bridge girders cause local stress-raising effects that need to be accounted for through a stress concentration factor (SCF) when performing fatigue analysis.

Prediction formulae for stress concentration factors at thickness transitions are available in the literature and the concept version of the new standard EN 1993-1-9. One of the shortcomings of the available prediction formulae is that the slope of the thickness transition is assumed to be always 1 to 4: the effects of other slopes (e.g. the more favourable 1:8) on the SCF are yet undocumented. Another shortcoming is that predictions for the SCF are usually only available at the toe of the thickness transition, at the location of the butt weld. Shifting the butt weld to a location further away from the thickness transition is beneficial for fatigue life: the open question is how the stress-raising effects vary with distance. Another aspect that requires investigation is the effect of thickness transitions on the vertical stresses in longitudinal (fillet) welds due to flange eccentricity.