Graduation Project Railway Canopies - Notches and Casting defects in Cast Iron

Strength of cast iron components containing notches and casting defects

Introduction

Grey cast iron components are made from steel scraps of different compositions, alloying elements, carburizers, etc… Depending on the production route used, the chemical composition, and microstructure can vary determining different properties. The microstructure of gray cast iron is a two-phase material with graphite flakes embedded in a steel matrix. This causes a more complex mechanical behaviour as compared to steel. Moreover, structural components cast in sand contain casting defects, such as pores and shrinkage porosities, that reduce the strength of the component as compared to the unflawed material. Moreover, notches, such as holes, act as stress raisers also determining a reduction of the strength.

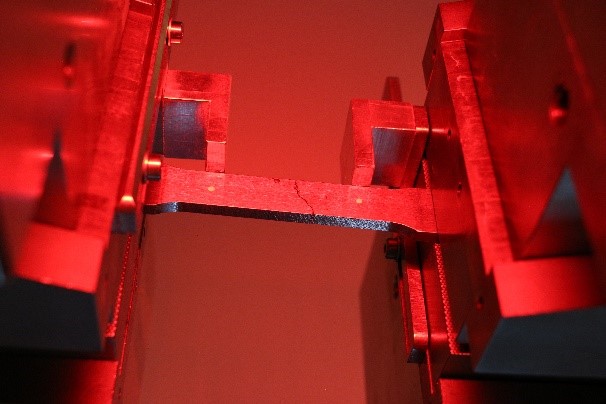

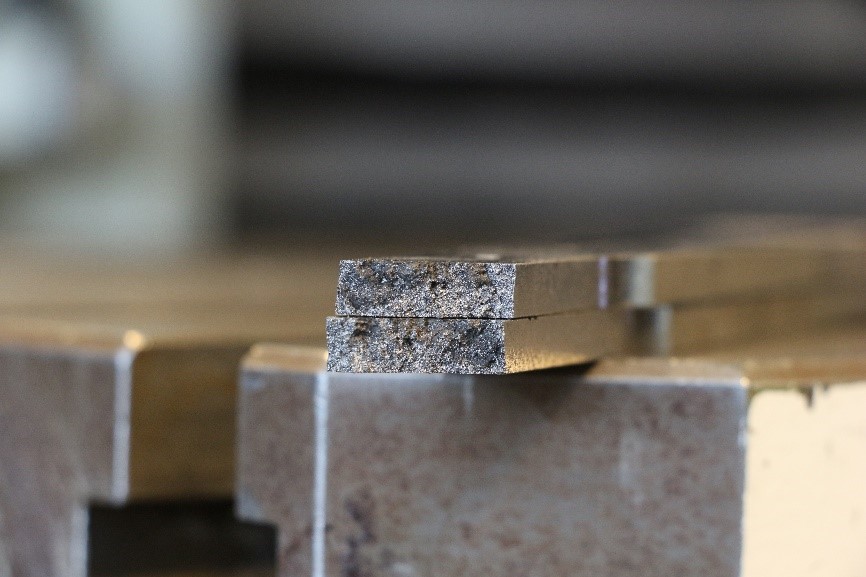

In a recent project, standard coupons of grey cast iron coming from columns of railway canopies from the railway stations of Groningen and Leeuwarden, see Figure 1, were tested in tension to determine the strength of the base material, see Figure 2. Moreover, notched specimens consisting of plates containing holes of different sizes were also tested to characterize the notch sensitivity.

Figure 1. Cast-iron columns at Leeuwarden station

Aim of the project

The proposed research project aims to characterize the strength of notched and flawed components of grey cast iron, and it is composed of experimental, analytical and numerical (finite element) work.

The material will be characterized in terms of toughness, using Charpy tests and fracture mechanics tests aiming to estimate the plane strain fracture toughness. Also, the strength of the base material under different loading conditions will be characterized (eg. bending loading, tension, compression,…). Other types of tests can be also included.

The numerical work consists of setting up numerical models sing the Finite Element Method to first calibrate and later deploy failure models for cast iron components containing notches and defects and subjected to both bending and tensile loading. The main goals are both the prediction of the mechanical behavior and failure condition.

(a) Test setup

(b) Fracture surface showing a casting defect (shaded grey area in the fracture surface)

(c) Test on a notched component

Figure 2. Tests on cast iron specimens

Supervisors

Prof.ir. Bert Snijder

Dr. Davide Leonetti

For more information, please contact Davide Leonetti