Redistribution of residual stresses in small specimen

Fatigue is one of the decisive factors for maintenance of steel structures. Accurately describing the fatigue crack growth rate is crucial in determining the fatigue life.

Introduction

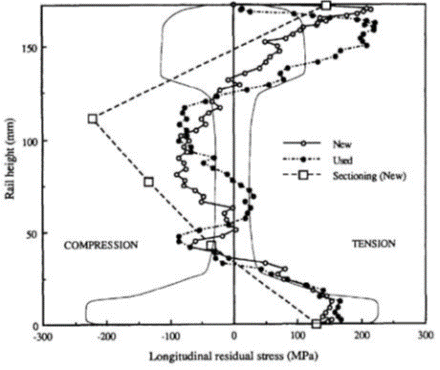

The fatigue crack growth rate is influenced by the residual stresses. Several techniques are available for the measurement of residual stresses such as the hole drilling method, X-ray diffraction, neutron diffraction and the crack compliance method. However often when preparing specimen for these measurements the structure needs to be cut in smaller pieces. Due to the self-balancing nature the residual stresses in a sample will redistribute. This leads to large uncertainty and the question when measuring the measured residual stresses on a small specimen does this still represent the real residual stresses in the whole structure. The focus of this project is on rails. Residual stresses in rails arise from manufacturing as well and redistribution during operation (see Figure 1). An accurate description of the residual stress field throughout the whole cross section of the rail is therefore important.

Figure 1. Residual stresses in new and used rail (Webster 1992)

This graduation projects aims to identify the influence of the specimen size on the residual stress distribution, develop a method to predict the residual stress distribution in the full rail based on a small specimen residual stress measurements and if required propose an experimental method to overcome this problem. To reach this goal, the use of (advanced) numerical models, as for instance the finite element method (FEM), are foreseen, complemented with a validation measurement.

Methodology

- Literature review

- State-of-the-art residual stress measurement techniques

- Residual stress fields in rails, for both as manufactured and used rail

- Finite Element (FE) modelling of residual stresses

- Numerical modelling

- Modelling of a residual stress field in a rail

- Development of a framework to mimic the cutting of small specimen

- Develop a method to calculate the residual stress distribution in a full rail based on small specimen experimental results.

- Experimental research

- Residual stress measurements on a rail to validate FE model, using for example hole drilling

- Proposal for residual stress measurements on full rails. These experiments are not necessarily done within this graduation research.

This project will be a collaboration between the TU/e, TU Delft, TNO and ProRail. The working location (TU/e, TNO, TU Delft) will be determined in consultation with student and supervisors.