Robotics

What a great time to be a student! The development of the digital world has supplied marvelous tools to control and optimize your designs. Innovation is exceeding the boundaries of your discipline, forcing to collaborate with others. Optimization of multiple unknowns increases the complexity but is very challenging and rewarding. We often forget it in the design phase, but one of these unknowns is the actual production and execution of your design. Robots can help to both work through the complexity and validate the feasibility of the actual build.

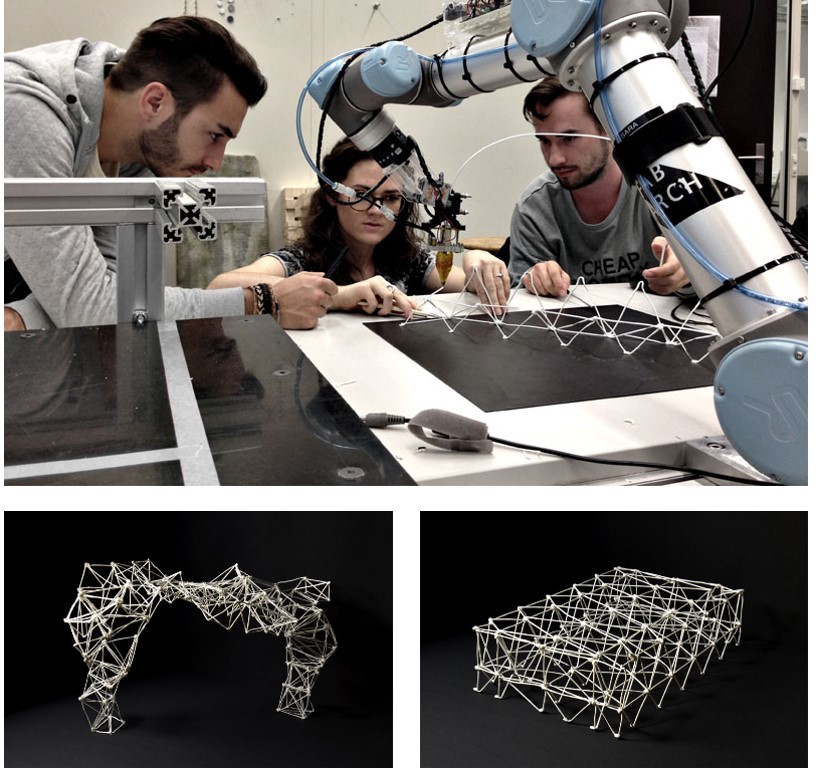

Figure 1: Study structural form optimization [ETH Zurich]

Previous generations did not succeed to make a healthy building industry. This sector, which is based on a very strong responsibility of architects as well structural industries engineers, takes approximately 50% of all primary raw materials and produces enormous amount of waste. This will drastically increase when the third world is rightfully claiming their increase in luxury. Therefore, change of the building industry is needed. The Dutch government’s program ‘Circular economy in 2050’ wants the primary material usage to be reduced by 50% in 2030 and to be fully circular in 2050. To fulfill these targets, we cannot solely rely on individual small new developments. The mindset of people must change and this should start at education level. Reduce, reuse and recycle are key words in this development asking for new building concepts with new biobased building materials. The new generation must find a way to use all available technical knowledge and explore new fields of innovation. The development of the digital world and robotics can support this.

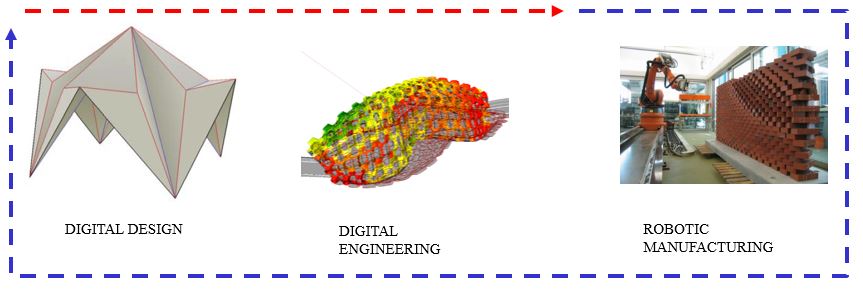

Traditionally, students worked individually on their graduation project. They often came up with fascinating designs, but did not share their learnings gained during the design process effectively with others. ‘Studios’ were therefore created, in which students collaborated and learnings were shared with many others. Studios create a rewarding work environment with valuable results on meaningful topics. Unfortunately, the focus in these Studios is more on the design and engineering of structures and the focus on the execution method is limited. Without the study on the execution method the designs will never be finished. A great design needs to be able to be produced and constructed. This is not an easy step. Designers often do not have the needed knowledge of production and/or construction. This can then result in friction between designers and builders and potentially cost increases or time delays due to late changes. When the design becomes more complex, the potential for a design that cannot be produced or constructed increases. To counteract this, a designer can gain experience by spending time in factories and building sites. The knowledge gained is the starting point for a new design process. How to execute the design is a question to be asked during the design process. This means that the type off machines that are used influences the design solutions. The design process is not a one way route from idea to product, it is an iterative process including the route from product to design, see Figure 2.

Figure 2: Adding manufacturing creates a full iterative design process

Robots can drill, cut, mill, polish and many other actions. Our two robots are capable of working together (called ‘multi move’) for example, by one robot that holds an element on the correct location while the other creates a connection.

With the two new robots, we have the possibility to produce complex geometries. We are free to choose the tools we connect to the robots, giving us a large range of design options. These tools become actually part of the design process. In some cases, the tool itself needs to be invented to be able to make the design.

Figure 3: The two new robots in the Structural Laboratory

The experience in our Unit to work with robots is still very limited. It will be a journey where teachers and students work close together and inspire each other. New knowledge will be shared within a Studio setting. Each student has its own project, but collaborations are set up when students need to tackle identical issues. Before the robots are used in a project, an extensive desk study is needed. All the movements that a robot will make are visualized in the program called Robotstudio. This way all movements of the robot can be optimized towards the required end product. But also for safety reasons it is essential to visualize the full motion of the robot and its tool.

The first students already started a few months ago programming movements and actions with different tools. In the first week of 2020 the two robots were placed in the Structures Laboratory. After a full safety check of the robots, the robots will be ready to perform the programmed movements and actions. These files will be shared documents for other students to study.

The umbrella that captures all research topics in our Studio is called “Resource Efficient Structural Design” (RESD). The course RESD was created in which multiple paths are explained to reduce the environmental footprint of structures. It covers three main areas:

- Reuse of buildings, elements and materials

- Use of new biobased materials

- Increase of material efficiency.

We see students in the Studio working on special detailing of elements to be reused in different settings, students weaving with biobased threads creating patterns that are related to the internal flow of forces and students creating form optimized shell structures where all detail connections are parametrical controlled. The robot will make the details, do the weaving, prefabricate the elements and connects them.

2020 is an exciting year for our Unit. There will be many interesting research projects for students. The robots themselves are not a research project, but can be used on all projects when helpful. Therefore, the correct training is needed. We are working on courses and a safety protocol to make this possible. A steep learning curve is expected. We are looking forward to see students enjoy working with these two new robots and the products they create.