Modular Buildings

The building industry is innovating in multiple areas and many different construction methods are being explored. One of these methods is modular construction. This is defined as using prefabricated elements repeatedly in different projects. In this article, three different companies explain their modular construction solutions to combat the housing shortage.

Sustainer Homes

By Thomas Steigenga

There are currently three major transitions in the construction industry: wood, prefabrication (prefab) and digitization. The added value of Sustainer Homes is the focus on the intersection of the three. We could start the Sustainer story from any direction, but most of the time we start with our sustainable driver: wood.

We no longer need to explain in detail the usefulness of wood in construction. The transition has really taken off since the VPRO's Tegenlicht documentary. At that time, Sustainer had already been developing its own modular wooden building system for several years. Every house that is built with our building system, results in a reduction of up to 70 tons of CO2. This has to do with both the emissions of a traditional building method and the capacity of wood to store carbon. A great contribution to the climate transition!

Figure 1: Placement of the Rabo Groenhuis, Utrecht

Over the past six years, together with a handful of pioneering colleagues, we have proven that you can build safely with wood. In terms of stability, acoustics, and fire safety, wood performs at least as well as traditional building materials. We all know that wood burns well in certain conditions. However, the burning of wood is very easy to predict, and the carbonization of the burnt layer also has an insulating effect on the rest of the beam or column. This makes it possible to say with much greater certainty than, for example, with steel, what is needed to make a building fireproof.

We can only make a real impact if our building system is applied on a large scale. To achieve that, we will have to be cost-competitive. As a material, wood is (at the moment) more expensive than traditional materials. Until wood enjoys the same advantages of the scale on which concrete and steel are used in production and logistics (and therefore becomes cheaper), we will also have to try other ways to reduce costs. This is where the second transition comes in: prefab.

Prefab means that you prepare the work at an external location where the conditions are more favourable than on the construction site itself. As a result, you can produce more cheaply, provided the transport costs are lower than the prefab advantage you achieve. In optimizing both proxies (transport costs and prefab advantage), the design of our module plays an important role, but more about that later.

Prefabrication (or industrialization) also taps into another trend in Dutch construction: conceptual building. Supply and demand are brought together in a number of concepts developed by the market, so that economies of scale can be achieved on both sides. On the supply side, a completely new project is traditionally set up for each individual house, building, street or district, with project members, architects, engineers, consultants, contractors and suppliers. Conceptual building opens up an approach to product thinking: selling and realizing a building design more than once. Of course, you can still take into account different customer options to make the product suitable for the user and location. This is also how the Rabo Groenhuis was created. You can often choose from different bay sizes and facade finishes. In this way you realize a product with a certain degree of standardization, so that the assembly line in the hall can be optimized accordingly. By going through approximately the same steps for an assembly process, you have plenty of room to learn, to implement improvements and to apply automations. A similar revolution has taken place in the car industry over the past hundred years.

Sustainer’s building system called the “.home” system (a kind of high-tech HSB based on Laminated Veneer Lumber - LVL) goes one step further than other conceptual propositions on the market. We set the standard for standardization at three levels: the element (e.g. the facade style), the sub-assembly (e.g. the floor) and the module. By making all the different configurations (in the millions) accessible via parametric software, you can facilitate the entire production chain of detached houses, terraced houses, two-person houses, social rental houses, and apartments with the same building system. And then you have endless flexibility within each category.

Because we use that module so often, we can also put a lot of time and effort into improving that module (including the software and the ecosystem around it) cyclically. Over the past six years we have gone from v1 to v5 in many iterations, of both hardware and software. Taking your product off the drawing board and actively testing it in the field is an essential part of creating a seasoned system. About 100 homes have now been realized in the system and many times more are planned, see Figure 1.

In fact, construction proxies come together in the module (besides the transport and prefab proxies mentioned earlier). This creates an integral building block of which you know that it allows each building to largely meet the set requirements, without having to go through a complicated process every time. A selection of the types of problems one might run into: building decrees, fire safety, acoustics, design flexibility, health, environmental impact, detachability, circularity, standardization, easy assembly, construction time, construction steps, transportability, climate regulation, installation integration, constructive stability, use of materials, Rc value, milling margins and operations, product properties, etc. We have a strong team of engineers in-house who carefully consider all these variables with every improvement or expansion of the system.

This brings us to the third transition to which we are responding: digitization. Our digital platform ties everything together. It serves not only as a memory of our building system and easy access to it for every new construction project, but also as an indispensable control of the entire production chain. As mentioned before, prefab thrives in repetitive processes with feedback loops for improvement. For optimal efficiency, different processes are closely coordinated: there is little room for unexpected construction errors. Digital control is indispensable for error-free construction. Our software delivers a 3D model to the assembly hall that is practically 1:1 detailed, including screws, installations, tapes, etc. Each element is matched to every other element to avoid surprises on the construction site. In addition, we attach a lot of data to the 3D model. For example, each element knows what it is, how long it takes to produce and assemble, and in which step it is needed in the assembly line. It also knows who the supplier is, what the theoretical lifespan is, where it is located, to which other elements it is connected, what the environmental impact is, what the weight and dimensions are, and anything else we think of in the future that might be useful. With the help of this data, the work preparation, purchasing and information provision of the assembly line can be largely automated. In addition, it provides a valuable digital foundation for organizing maintenance and reuse in the future.

To wrap up the story, let’s make the step to practice. Last summer, developing contractor Koopmans construction group and supplier geWOONhout completed the first four terraced houses in the Sustainer.home system, see Figure 2. This is the first step towards large-scale and competitive application of our system, with enormous potential for impact. A plus and minus is that this house is almost indistinguishable from a traditional house. The house plan as we know it today in the Netherlands is largely a result of traditional building methods. What if we could also embrace the modular philosophy in home design? And what if our new housing stock makes optimal use of all the possibilities offered by modular construction in wood? The future will show us!

Figure 2: Houtbaar Huis Concepthouse, Hengelose Es, Hengelo

Barli

By Twan Vrijsen

About 800 homes will be built this year in Uden, barely half an hour from Eindhoven. Not in a new residential area, but inside: in the Barli housing factory. The Brabant company swears by 3D production of modular homes built in wood. And there are very few in the Netherlands who do this on such a large scale, explains director John van der Doelen.

“Last year, just over 800 trucks with more than 600 ready-made homes drove off our site. And in the coming years, we will more than double that," says Van der Doelen, see Figure 3. The proof lies in the enormous production halls, with a total area of 32.000 m2, of Barli. At this very moment, those halls are filled with homes, ready for transport. Kitchen, bathroom, installations: everything is already in there.

"We have noticed in recent years that our modular and sustainable way of construction fits very well with the upscaling demanded by the housing market," says director John van der Doelen. “For example, for housing associations, who are looking for an affordable solution that is quickly available. Sometimes temporary, but more and more permanent. Project developers are also discovering that you can realize special projects modularly. This is partly because our wood construction method contributes to the idea of circularity and sustainability.”

Figure 3: John van der Doelen in the Barli housing factory in Uden

Better environmental performance

The recent report ‘Woningbouw in hout’ underlines this. Timber construction delivers better environmental performance than other construction methods. With modular building, you also limit the number of transport movements, CO2 emissions, and nuisance on location. "That report shows very nicely that modular construction as we do it also fits very well with the required quality, speed, and affordability. Comparatively, construction costs are lower, the construction speed is higher, and we also meet all quality requirements!"

The availability of wood is no problem, even if we will build many more houses in wood. This is shown by recent research by Wageningen University & Research. "Every year, one billion m3 of wood is added, and the harvest is only 600 million m3/year. So there is no shortage of wood; the European forest is even growing."

Mass customization

The idea that building with blocks like LEGO blocks leads to straightforward homes is a big misunderstanding, according to Van der Doelen. “Stacking and switching modules makes the possibilities very customizable. In Eindhoven, for example, we will build 45 wooden houses in the OAK Bosrijk project, see Figure 4. There are no fewer than 11 different housing types for various target groups; from 70 m2 to spacious family homes of over 200 m2." Barli is part of the winning tender team, in which various specialists designed an integral plan. The TU/e is also involved. “Together, we are looking to see if we can make the plan even more sustainable. Almost three-quarters of the houses already consist of circular materials. For example, we make the facades from locally harvested poplar wood. The houses can also be dismantled: we can move them in the future."

Figure 4: OAK Bosrijk project

Data-driven production

Barli's strong growth ambition comes with the necessary challenges, not only in production but also in work preparation and engineering. Based on a digital roadmap, the company is taking significant steps towards data-driven production. Senior Tekla Engineer Bart van der Kallen explains: “Think of the data-technical unambiguous recording of building blocks and construction concepts and more efficient ánd paperless management of our production. But also the automation of engineering processes resulting in validated source data or using a BIM protocol to promote collaboration with third parties. One of the first results is developing an innovative tool in Tekla. With the tool we can automate manual export routines from a BIM model. That saves much time and it excludes possible errors. Within the model it is possible, for example, to live track which elements are already in production."

In the urge to industrialize, one housing factory after another is being built in the Netherlands, often by the traditional building companies. “I can safely say that the developments at those traditional builders are still far from the way we do it ,” concludes John van der Doelen. Alluding to the fact that others create mostly 2D elements, whereas Barli chooses to produce 3D elements.

MOOS

by Charlotte Heesbeen

Our world can be a great place to live in, but the truth is that this is not the case for all of us. We are facing severe problems that are threatening our existence. We have to react by radically and structurally changing the status quo of the construction industry. That sounds scary, but with little guts, we can do it! MOOS, short for In The Middle Of Our Street, has picked up the gauntlet to respond to the situation promptly and responsibly. Essentially, MOOS is here to contribute to two enormous social challenges: firstly, the painful shortfall of houses and, secondly, helping to create a circular building environment. The way to get there is by creating a comfortable home for everyone, see Figure 5.

The MOOS building system is a realistic solution. Realistic, in our eyes, is a technically feasible system at a competitive price and realized at the glimpse of an eye. An answer rooted in industrial and prefabricated production is therefore apparent. Beyond that, our solution excels at being circular and contains a significant degree of bio-based and secondary building materials. Let us have a closer look at how we aim to combine this in practice.

Figure 5: Comfortable houses for everyone

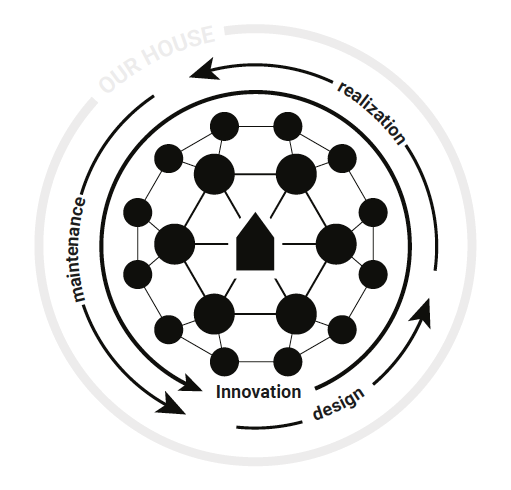

You can find the key to living up to the expectation in our partner ecosystem, see Figure 6. In it, we let go of the traditional top-down hierarchy, headed by a general contractor. Instead, we have realized a unique collaboration of experts in the field. All of our partners have years of experience and are independent builders and advisors. They are similar in having committed to designing comfortable houses. Also, the built solutions will be fit for the entire building lifecycle and beyond. An example of a successful collaboration is the choice for recycled concrete floors in an otherwise timber construction. It allowed us to create synergy between multiple factors. To reuse the flow of high-quality building debris and guarantee an acoustically comfortable interior. And also to create a building system that is fit for different building configurations, ranging from two-story gallery layouts to higher buildings arranged around a core.

The process to create our buildings is digitally steered and tracked, from design to the high-quality reuse of resources. We tap from a library of standard and modular units during the design phases to create a customized solution. In the 'initiative' phase, we use a configurator to estimate an optimal solution for a specific location and demand. After realization, we keep track of the building in a digital twin. This way, the information is ready for the reuse of MOOS modules or the repurposing of building materials in comfortable housing that will be needed by then.

Figure 6: MOOS Ecosystem

Making an impact is not something to do alone. We are continuously looking for innovators and go-getters to strengthen our team. If you are curious after reading this, we are happy to show you around the LAB-house in Zaandam, see Figure 7.

Figure 7: The LAB-house in Zaandam