Topping off a brutalist icon

One Central Plaza is an iconic landmark in the heart of Dublin, previously known as the Central Bank building and designed by brutalist architect Sam Stephenson in the late 1960s. It is a prominent feature on the Dublin skyline and visible from multiple points throughout the city. The building is now being transformed by Hines in partnership with the Peterson Group, creating a new destination called Central Plaza, bringing together offices, retail, and restaurants.

The crown of the renovation is a two-story glass-roofed structure, designed by architect Henry J. Lyons, that will top off this icon. Octatube has been awarded the contract to engineer and build the glass and steel structure. To make the rooftop structure as transparent as possible, most of the roof, as well as the facade, is made of glass. The design of the roof opts for a fully glazed corner, which will offer visitors unrivaled and uninterrupted 360-degree views of the city. The roof will be built on the existing roof structure, which is special and challenging in terms of design and structural engineering.

Challenges

The new steel rooftop structure measures 42.5 x 27.5 x 6 meters and weighs more than 200 tons. It consists of multiple steel RHS beams (400x200 mm and 200x100 mm) that are connected to each other by hidden bolted connections. The structure is a monolithic steel frame without expansion joints. This presents a challenge to our structural engineers in regard to thermal expansion. How can we make sure the roof structure is able to cope with variations in temperature and the coexisting deformations? The roof is connected to the existing building on eight primary supports on the center of the existing building, and twenty-eight hinged column supports around the perimeter of the roof. All except one of the primary supports allow movement in one or more directions to make sure no loads build up within the system due to temperature variations. The one fully constrained support keeps the roof in place. When the temperature fluctuates, and thermal expansion occurs, the roof is designed in such a way that it can slide over the facade, enabling the roof to expand and retract respectively 30 and 15 millimeters. Meticulous detailing of the facade to roof connection is required to allow this movement.

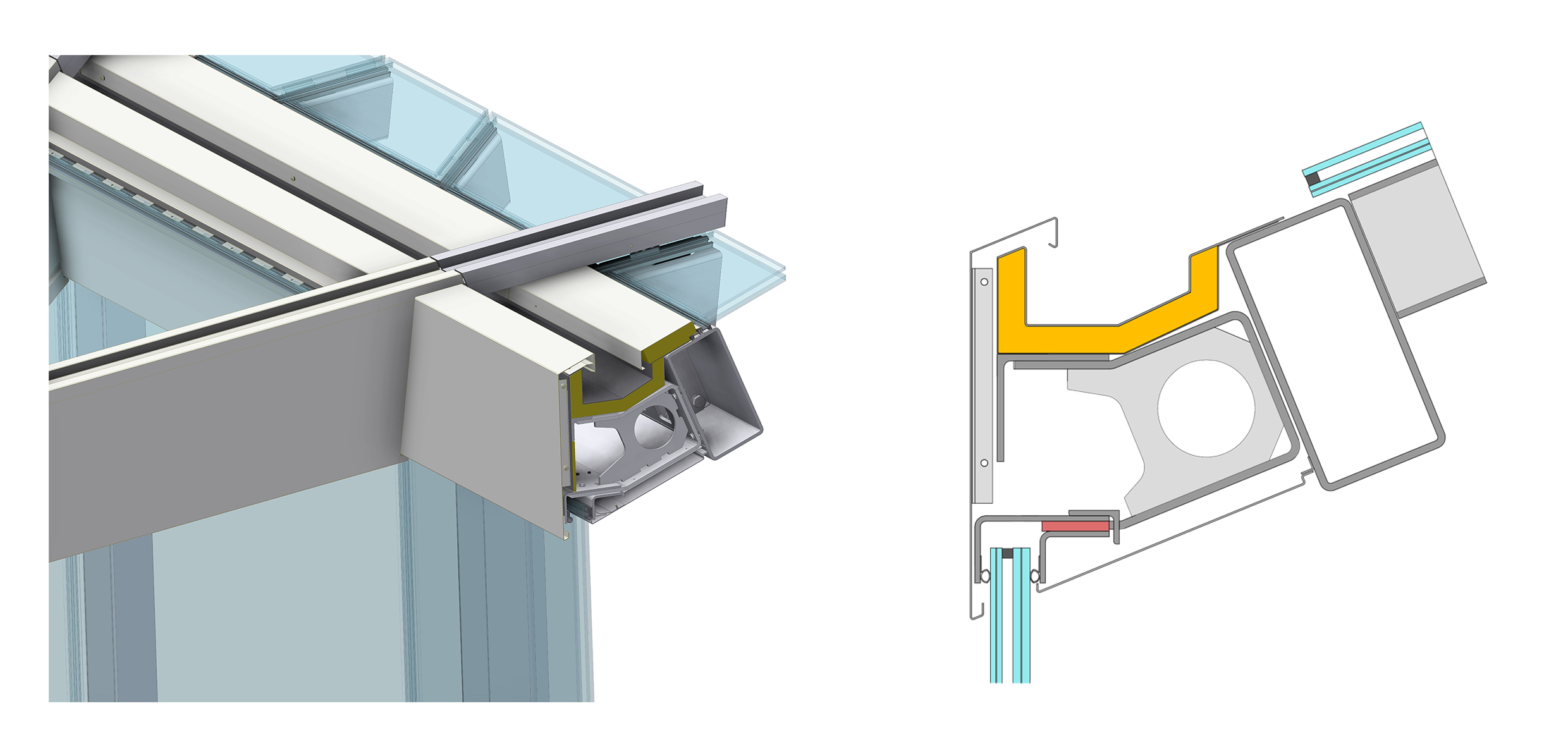

Detailing – top facade supporting structure

The top detail of the facade is located where the facade glazing transitions to the roof. This detail is created using two L-profiles, which are bolted together into a U-shape. On each of the profiles, a rubber is placed to prevent contact between metal and glass. Every time the roof moves horizontally due to thermal expansion, the facade glazing would be pushed and pulled, resulting in cold bending of the facade glazing. To prevent the vertical movement of the roof to influence the facade glazing, 40 millimeters of space is kept free between the L-profiles and the glazing.

Figure 1: One Central Plaza Rendering (image by Henry J. Lyons)

Fully glazed corners

The system works the same all around the facade, with the exception of the eight corner panels, the fully glazed corners. When the roof expands or retracts, the glazed corners cannot follow due to their geometrical constraints and will be pushed open. To prevent this from happening, the top facade supporting structure is disconnected from the roof itself.

Figure 2: Glass top connection

Perimeter column connection

The Central Plaza building is quite unique; the structure comprises suspended floor slabs held up by perimeter Macalloy tension rods that are supported back to the central core at roof level. A Brutalist characteristic: exposing the building’s structure. Live loading on the floors (i.e., people moving around) results in elongation of the tension rods. Thus, the outer perimeter of the 10th floor has relatively large deformations. To reduce the impact on the roof structure, additional compact bearing rubbers are applied at the anchors. When the floor moves downward due to live loading on the lower floors, the influence on the column is negated, which results in the reduction of loads on the roofs.

Realizing challenging architecture

One Central Plaza is currently being realized in Dublin. Realizing a challenging structure like this one is our driving force at Octatube. It requires thorough foundation embedded in structural engineering. Through extensive iterative calculations, detailed drawing, testing, and creativity, the most challenging projects can be realized.