The Failure Behavior of Axially Loaded Sandwich Panels

Sandwich panels are commonly used in roofs and façades to insulate and enclose the building. In this situation, another load bearing structure supports the panels. However, what if sandwich panels become the load-bearing structure? Then, material could be saved since the sandwich panel is now multifunctional and no additional insulation and enclosure for the building is needed. Due to different loading applications, the failure behavior of sandwich panels as load-bearing walls differs from the failure behavior of sandwich panels as roof or façade elements. Therefore, this research investigates the failure behavior and load-bearing capacity of a sandwich panel wall.

The sandwich panels in this research are fabricated at Kingspan Unidek B.V. The panels consist of two wood-based faces, which resist the tensile and compressive stresses, and a rigid foam core that resists the shear stresses. The faces of the panel consist of a cement-bonded particleboard for fire safety reasons [1]. The rigid foam core consists of Expanded Polystyrene (EPS).

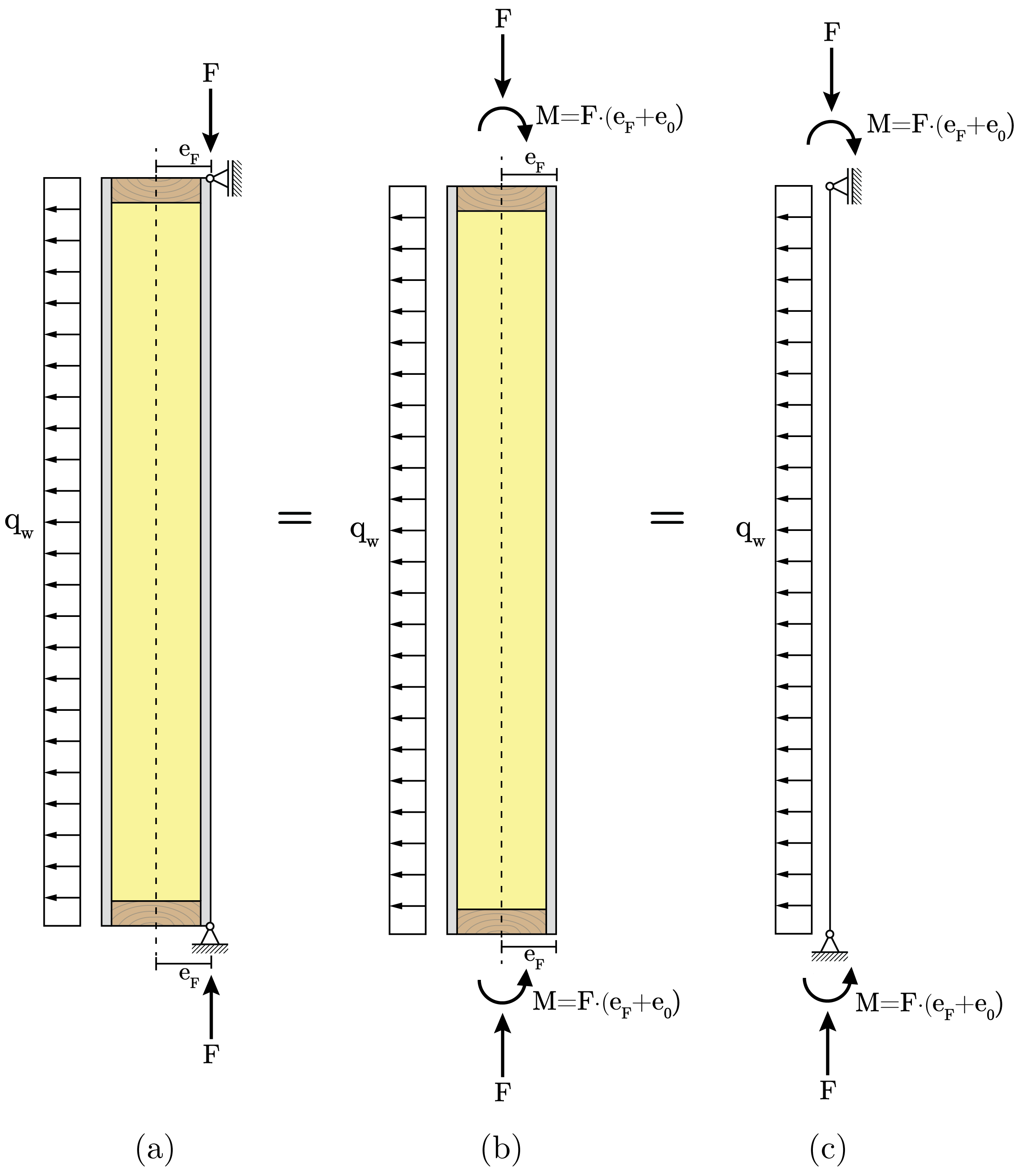

When considering sandwich panels as load-bearing walls, several challenges arise. The panel is now loaded by an axial and wind load and is connected to a floor. When the floor is loaded with a distributed load, the floor bends and rotates around the inner face of the panel. Therefore, the floor is only supported at the inner face, and the axial load will also be situated at this location. Consequently, the neutral line of the sandwich panel is not in line with the line through the supports. This results in an additional moment equal to the load eccentricity multiplied by the axial force. The corresponding mechanical scheme is visible in Figure 1.

Figure 1: Mechanical scheme

Several failure modes are possible for axially loaded sandwich panels. In this research, the seven most important failure modes will be investigated and are listed below [2]–[4]:

Failure due to the deformation limit, tensile or compressive failure of the faces, wrinkling failure of the faces, shear failure of the core, interface failure, global buckling, and connection failure.

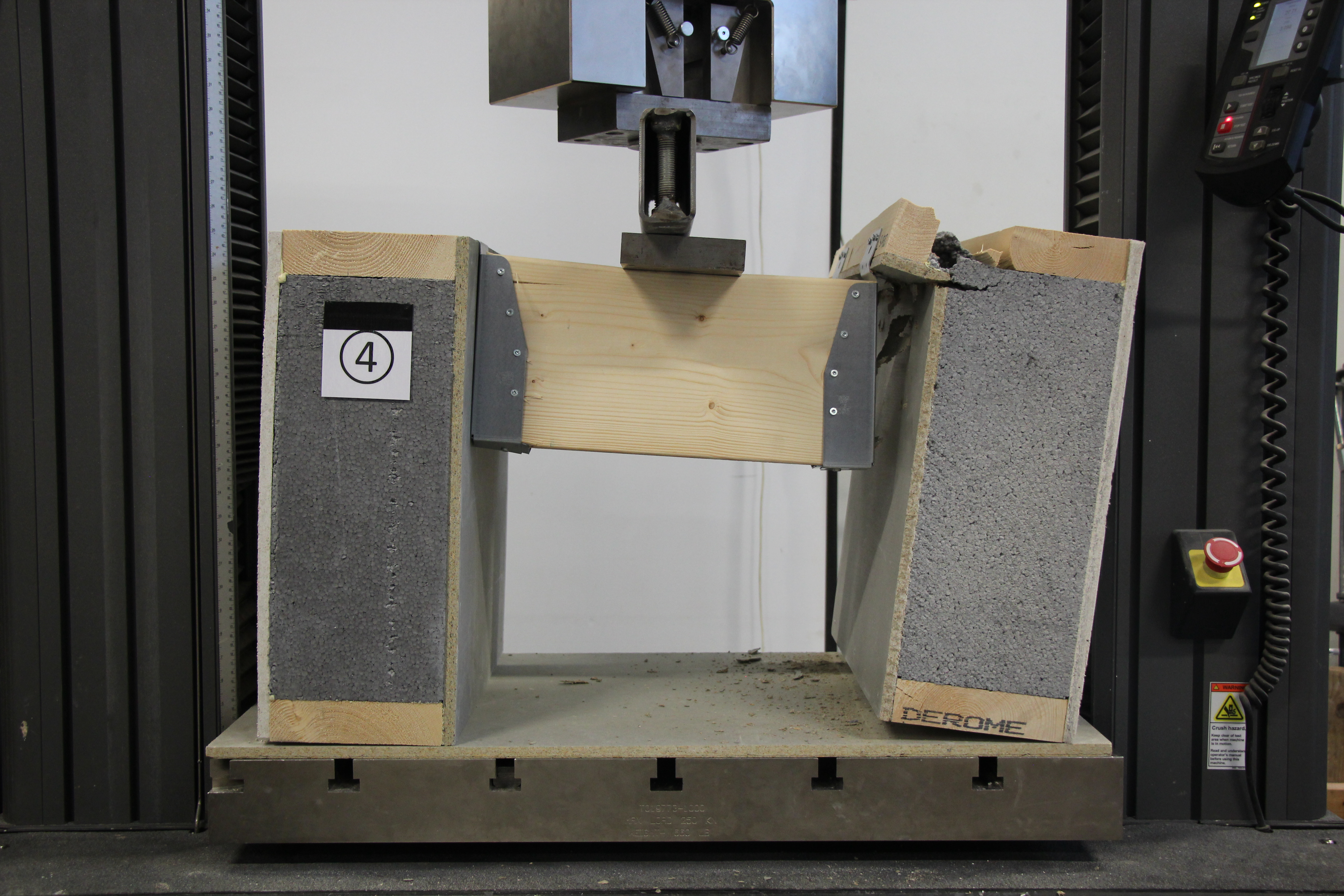

To investigate the connection failure, a preliminary test was already executed to study the connection's capacity. This test consisted of two sandwich panels of 500 by 500 by 170 millimeters and a floor beam connected in between the panels. During the test, the connection failed before the sandwich panel failed and a maximum load of 84 kN was reached, which is 42 kN per panel. In Figure 2, one result of the test is visible.

Figure 2: Result one connection test

In the current phase of this research, an analytical model is created which determines the deformations and stresses of the different failure modes. Additionally, the model predicts which failure mode will be governing. This model will be validated with laboratory research. The laboratory research will start with determining the material properties of the cement-bonded particleboard. Then, sandwich panels with dimensions commonly found in residential buildings will be tested. During this test, the panel will be axially loaded and a distinction will be made between testing with and without a horizontal wind load. In addition to this test, a more elaborated connection test will be performed.

In the last phase of this research, the analytical model and laboratory research can be used to determine the maximum axial load and the governing failure mode of the sandwich panels. With this information, the panels can be used as load-bearing elements in buildings.

References list:

[1] European Committee for Standardization, EN 13501-1: Fire classification of construction products and building elements - Part 1: Classification using data from reaction to fire tests. 2007.

[2] J. M. Davies, Ed., Lightweight sandwich construction. London ; Malden, MA: Blackwell Science, 2001.

[3] H.G. Allen, Analysis and Design of Structural Sandwich Panels. Southampton: Pergamon Press, 1969.

[4] S. Käpplein and T. Misiek, “Axially loaded sandwich panels,” p. 72, Jun. 2011.