Master Thesis of Tom Diks

One of the most significant challenges of our time is the major building task of offering a home to all people in the Netherlands. Living in the city continues to be increasingly popular, and this is not expected to slow down. However, most cities have limited space and therefore focus on densification nowadays. A result of this is that more and more towers show up in cities and get higher. Besides the build-more-houses challenge, there is much to be done on the environmental impact of these buildings. Unfortunately, these concrete giants belong to one of the biggest environmental polluters. Enough reason to do some research into making concrete high-rise buildings more sustainable. This research was conducted together with the chair of sustainment of structures and BAM Advies & Engineering.

Parameter study

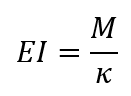

A parameter study was chosen for this research. This means that research has been carried out per high-rise building parameter to determine how significantly this influences the environmental impact. An overview of the investigated parameters with the corresponding research domain can be seen in Table 1. This

is done for several different bracing systems done at different heights. A default design has been drawn up for each of these combinations in which all parameters are constant. Then each parameter is individually varied over a certain domain. Each generated variant is checked for maximum compressive strength in the ultimate limit state (ULS) and for maximum deformation at the top in the serviceability limit state (SLS). Each variant is varied in concrete class and reinforcement ratio. The variant that meets the ULS & SLS with the lowest environmental impact is selected. In this way, a trend line can be drawn up per parameter on the influence of sustainability.

Table 1: Parameters with research domain and default value for core and facade

Research boundaries

Terms such as sustainability and high-rise buildings are broad areas of research. Therefore, choices had to be made on what to focus on. Regarding sustainability, the research looked purely at the environmental impact of the embodied carbon released during the production process [phase A1-A3] of the materials concrete and reinforcement of the bracing system. In terms of high-rise buildings, only concrete high-rise buildings between 100 and 200 meters were considered. The foundation is not taken into account, and the tower is modeled in a fixed connection. To compensate for this, a more stringent deflection requirement of 1/750 has been applied. Finally, three different bracing systems are investigated: the core, extended core and facade tube.

Method

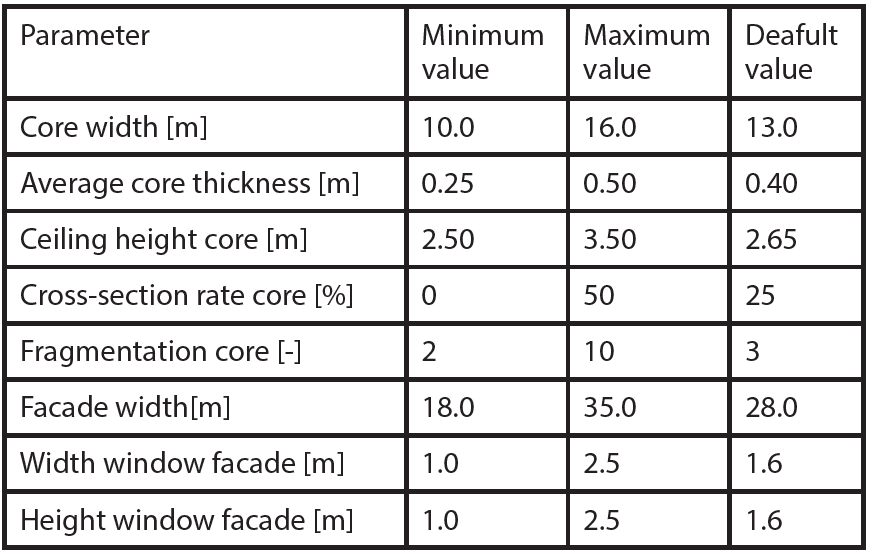

Thousands of high-rise designs were calculated for the study. That is why a lot of effort has gone into a fully automated parametric structural analysis. Rhino+Grasshopper was used for this. From Grasshopper a geometry of the bracing structure is created. Also supports, a mesh and (wind)loads are conform Eurocode and national annex. An important part is determining the bending stiffness (see next paragraph). When all necessary structural information has been determined, a finite element analysis is performed. Karamba 3D was used for this (see Figure 1). All variants were calculated using a first-order linear-elastic theory.

Figure 1: Default design core model view (left) and stress pattern (right)

Bending stiffness

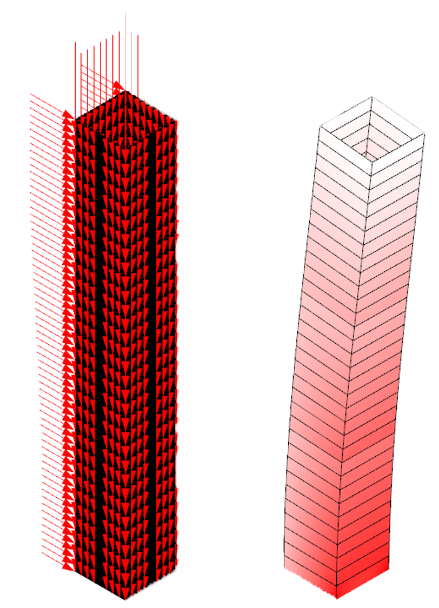

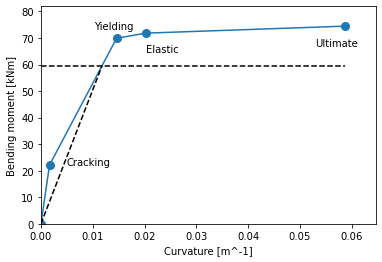

The core and extended core are assumed to behave as one rigid cross-section. This means that plane sections remain plane. This means that an M-N-κ diagram is allowed to be used. For reinforced concrete this means that the four characteristic points (cracking, yielding, end of elastic concrete, and ultimate) are determined. Based on the characteristic moment in the cross-section, a global bending stiffness EI can be determined as follow:

Because each floor can have a different normal force and crosssection, each floor's bending stiffness is determined. To automate this process, a python script has been written that determines the bending stiffness in a few milliseconds using the M-N-κ principle. The four characteristic points are iteratively determined by finding equilibrium in the vertical direction. An example of an M-N-κ diagram of a story is shown in Figure 2.

Figure 2: Quasi-linear determination of bending stiffness

Quantification of sustainability

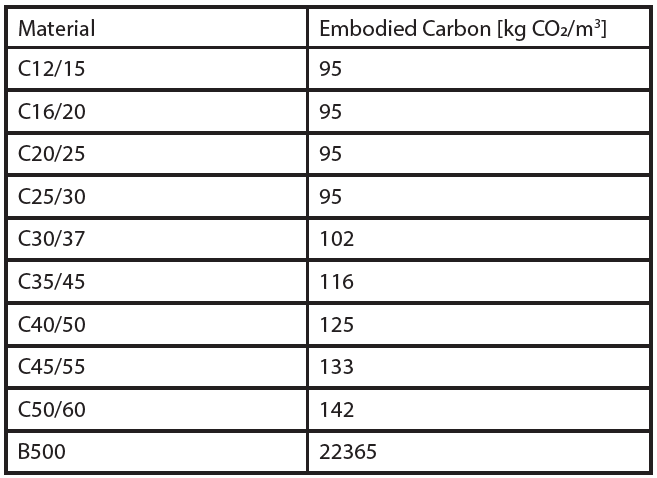

Once the bracing system meets the structural checks, it is known how much concrete of which concrete class is needed and how much reinforcement is needed. The environmental impact of these required materials is determined for each variant. This is done based on embodied carbon expressed in CO2-equivalent. This was chosen because CO2 has the greatest impact of all environmental impact indicators (EN 15804). In addition, CO2 is

relatively easy to quantify and compare.

Concrete

Concrete comes in many different mixtures. As standard, most mixtures are coarse and fine aggregates, water and binding agents, and admixtures. For the quantification of the embodied carbon, each component was investigated. Additional attention was paid to the binding material, because this has the most significant influence and can differ greatly. By far, the most commonly used binder is cement, particularly Portland cement. For this study, a representative CEM-III/B has always been used.

Reinforcement

Since reinforcement is a homogeneous material, there is much less variation here. For the study, only B500 was used for the analysis. This is the most common material. This reinforcement has a relatively large environmental impact. Because a maximum of 4 percent longitudinal reinforcement is allowed in a concrete cross-section, the total reinforcement volume is limited. However, due to the high emissions, reinforcement is responsible for a large part of the total impact. An overview of all embodied carbon per material is shown in Table 2.

Table 2: Embodied carbon per material

Durability

The longer something lasts, the more sustainable it is. It is, therefore, important that a structure can be used for a long time. If you look at the reason for the end-of-life of buildings, it is often not the technical lifespan but another aspect that causes early end-of-life. High-rise bracing structures have little to no flexibility once built. It is therefore crucial that the design choices take into account a future-proof design. Several practical aspects are, for example, the maximum vertical transport capacity that fits in the core. In addition, a small opening percentage with a facade tube and a low ceiling height is often less flexible and therefore not really future-proof.

What’s next?

Since the research is still going on, it is too soon to publish definitive results. However, by the time the KOersief 114 is published, I will most likely have finished the research, so do not hesitate to contact me if you would like to know more about the research!

Figures: Header: https://www.rijnmond.nl/zalmhaventoren