A Perfect Fit For a High-Tech Dome

Walking into the gigantic glass dome of the AFAS Experience Center, it is hard not to be impressed. With a diameter of 42 meters and a height of over 24 meters the majestic structure covers a theatre that can house up to 850 people. Between the theatre and the glass dome enough space is left to fit a foyer with a capacity of over 625 people. Octatube engineered and built this impressive glass dome, designed by Steef van der Veldt and Just Architects, with its horizontal lines and triangular glass panels.

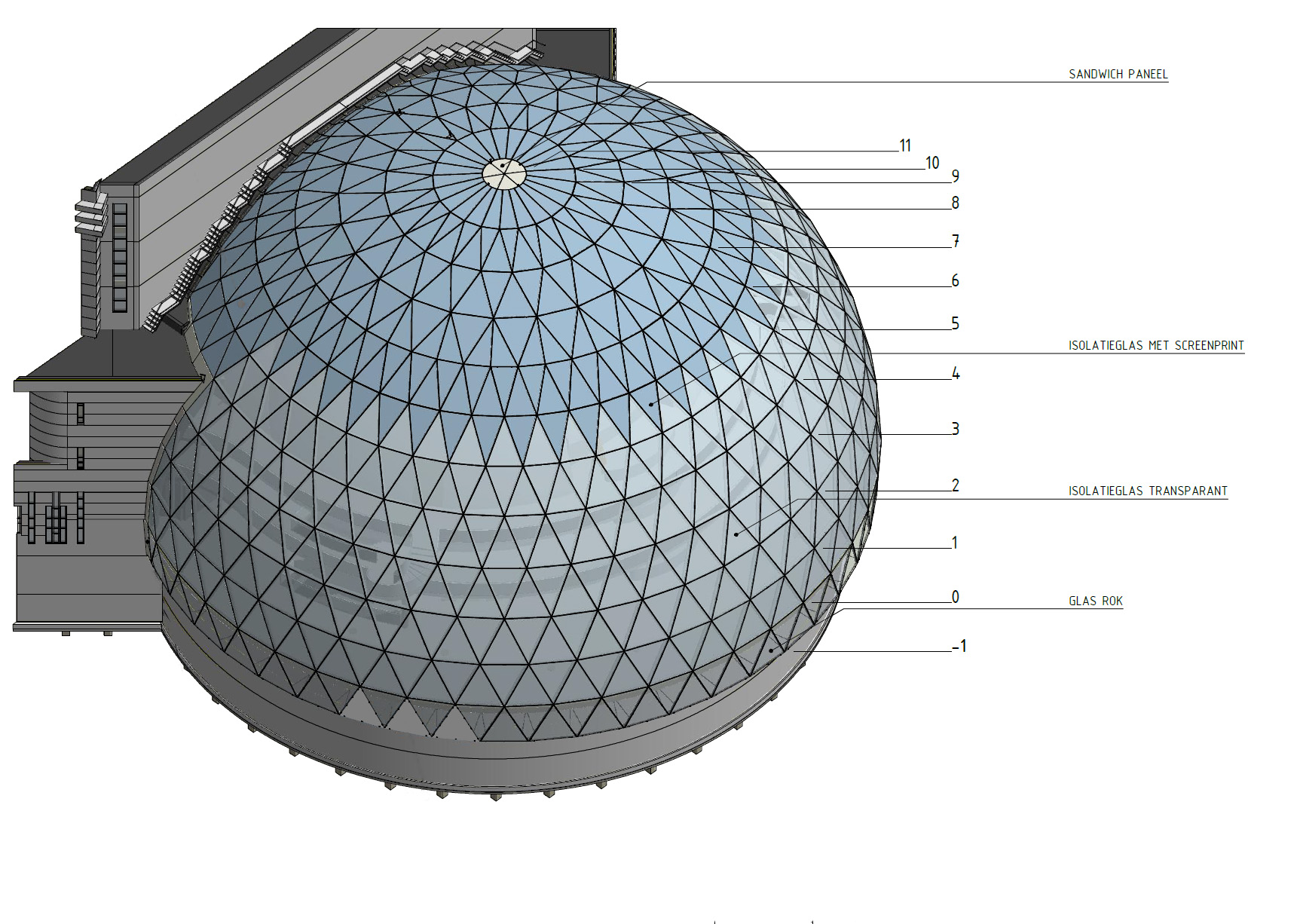

The most important question we had to answer during the design phase was: ’’how can we design a structure in which the triangular glass panels are neatly divided over the dome, without any disturbing deviations in the pattern?’’ We started with the largest possible shape at the base of the structure: a triangular glass panel of 3.2 meters. Towards the top the panels gradually become smaller, building the dome up with a total of 11 horizontal rings. Between the 9th and 10th ring, the number of glass panels per ring goes from 48 to 24, preventing the triangular panels from becoming too sharp and therefore difficult to produce. The steel rings are interconnected with tubes that follow the distribution of the glass panels.

Figure 1: Division of triangular glass panels across the dome into 11 horizontal rings

The dome is covered with more than a thousand glass panels, built up out of an inner laminated pane of two by eight millimeters, a 16 millimeters argon-filled spacer and an outer pane of approximately 10 millimeters thick single safety glass. The first ring is positioned below ground level and stops right above the water surface surrounding the dome. The glass in this bottom ring has a perforated blue screen print to reduce reflections from the water. From the seventh ring onwards, the glass is provided with a dense screen print in the same blue color. This print serves as sun shading. On the inside, these glass panels are covered with acoustic panels.

The architectural essence was the visual disconnection of the glass skin from the main steel structure. We designed cast steel, dark blue, powder coated supports to attach the glass panels to the steel structure, making it seem as if the glass is loosely folded over the steel structure.

Figure 2: A support to visually disconnect the glass skin from the main steel structure

A space of 24 millimeters is required between the glass panels in order to attach them blindly to the blue supports. The sealing gaskets and spacers closely match the color of the supports. The feet of the supports flow over into the sealing gaskets and because everything has the same color it visually ‘disappears’. From the outside the glass connection is not visible, creating a visually clean dome. In addition to these supports, we also custom-made the sealing gaskets for an optimal closure of the glass panels.

Although the dome appears to be completely spherical from the outside, there is actually a bite out of it. This leads to a drastic loss of stiffness in a structure which is naturally rigid due to its shape. Because the dome should not be allowed to pull or push against the surrounding structures, we designed a, 500 millimeters in diameter, edge beam around the connection to the theatre tower in order to redirect the forces. This beam is structurally disconnected from the tower. The one meter wide dilatation created at the connection is filled with an insulated zinc gutter.

Figure 3: Edge beam around connection to theatre tower

The dome is connected to the theatre tower at three support points, which is necessary because a lot of snow can theoretically fall here. The supports provide vertical force transmission. We increased the wall thickness of the structure around the edge beam as well, from 6 to 12 millimeters.

The support points are designed as spherical plain bearings. The two outer supports can move freely horizontally. The middle support is horizontally restricted in the plane of the tower. It is the fixed point from which the dome can deform due to loads, thermal expansion, and shrinkage.

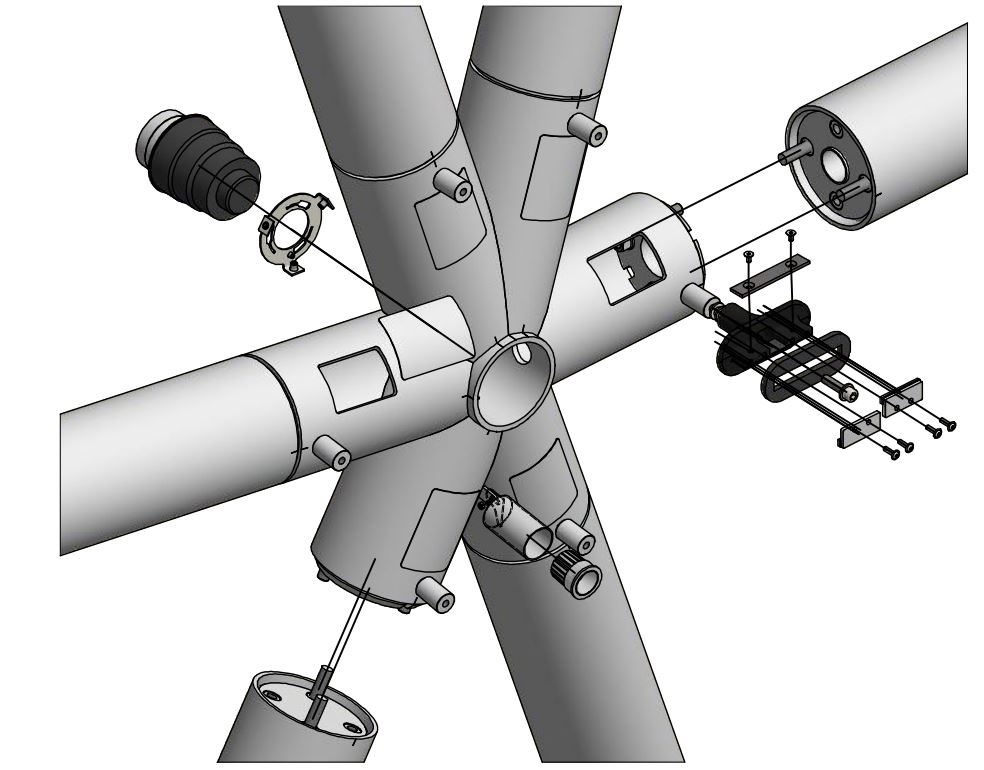

All supports of the steel structure on ground floor level can move perpendicular to the dome center. To prevent damage from the expansion forces on the floor, the dome is structurally disconnected from the floor. An exception forms the large edge beam, which is firmly anchored to the floor and, together with the middle support, creates a fixed framework for the dome. The steel structure of the dome is made of hollow tubes with a diameter of 178 millimeters. Each bespoke designed node connects six tubes. At the center of this node we designed a short circular tube with a diameter of 140 millimeters perpendicular to the node to which the tubes are connected. Integrated in this centerpiece is a light spot that can be rotated individually in every direction. All the wiring and controllers are placed within the tubes.

Figure 4: Detail of the specially designed nodes

To be certain that the nodes and tubes would fit together, mock-ups are made and tested. Samples were made of the left over cuttings, restoring anomalies would have taken up a lot of extra time

We chose not to use large prefabricated frames, but to work with separate tubes and nodes that we assembled on site. Large elements need to be planned, because multiple people have to collaborate and a large crane is required, whereas smaller elements provide easier handling and create flexibility. We fully assembled the gigantic tubular steel construction on site with only three people: one person operating the crane and the other two mounting elements in place. The dome was built up similar to a kind of igloo, in five days per ring.

Figure 5: Final ring installed at the top of the dome

Closing the dome at the top was an exciting moment. A dome only works well structurally once it is finished. When there is still a gap at the top, the dome could start leaning inwards as a result of its own weight. We placed the final ring, including six mounted tubes, as one piece into the dome. There was no certainty that the three by three meters prefabricated element would fit. Fortunately, the element fitted perfectly!