Building D(emountable)

How to build an office that can be completely dismantled in the future, uses minimal material, and has only dry connections? That was the challenge for Building D(emountable). Following A, B, and C, this building block is the fourth block in an office cluster owned and designed by architectural office cepezed in Delft. The hybrid steel-wood structure is intended to be fully future-proof and demountable. The prefab building elements remain visible, and connections are dry joints with building installations cleverly integrated. All these choices have resulted in a considerably shorter construction time. Installation of the steel frame and floors took only four weeks.

Circular design philosophy

Building D, completed in 2019, is a new four-layer rectangular office building in an ensemble of three revitalized early 20th-century monumental buildings owned and partly used by cepezed. The existing buildings were initially built as a laboratory for the structural department of mechanics and maritime engineering of the Delft University of Technology. Later its function was a museum of technology.

In 2014 cepezed transformed the buildings into their own architectural offices, adding a lightweight, transparent volume that connects the three existing buildings. The fourth building had minimal historical value and was, therefore, substituted by a new office volume in 2019, currently used by external renters. The design philosophy for this new part, Building D, fits perfectly in a circular economy. The various building materials used are implemented in separate layers that are fully accessible and individually replaceable after their respective lifespans. The connections in the steel structure are all bolted; no welding was needed on the building site. The building can be demounted just as fast as it was built.

Lightweight hybrid construction

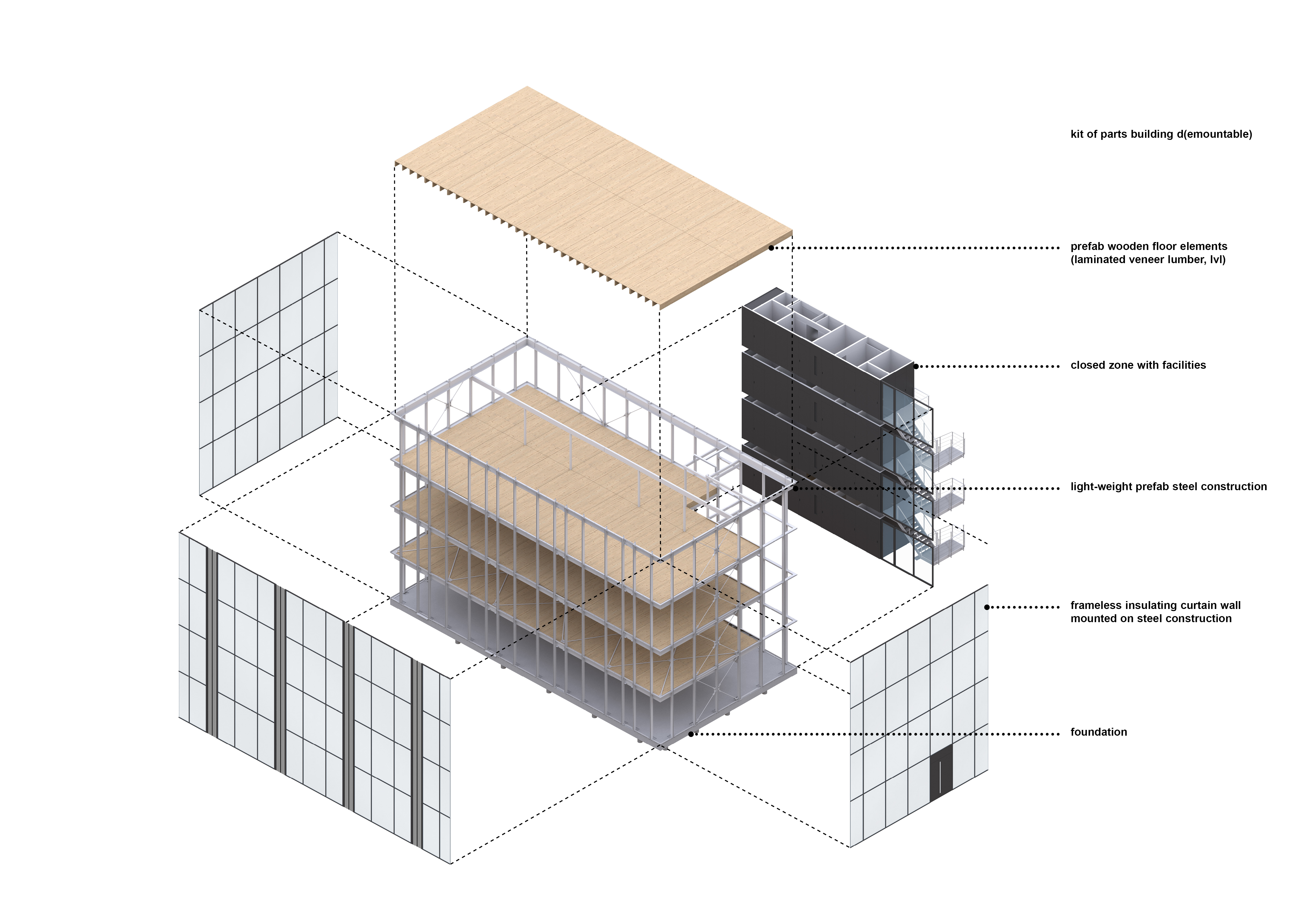

The existing foundation could not be reused since specific wooden piles were in bad condition. To minimize the loads on the adjusted foundation, the entire new structure was designed with lightweight materials: wood and steel, see Figure 1.

Figure 1: Kit of Parts

The new volume has four rectangular floor plans of 11 by 21.5 meters and is 12.5 meters high. The load-bearing steel structure has three bearing lines of columns in the external facades and a longitudinal internal beam in the middle of the plan. The floors are built out of a wooden Kerto system: Laminated Veneer Lumber (LVL) consisting of a 25-millimeter thick glued top plate on 360 by 45 millimeter ribs. The wooden floors are produced as 11-meter-long elements, covering the entire width of the building at a time. Structurally they span maximally 6.4 meters (from the external facade to the middle steel beam). The elements are connected to create diaphragm action.

Integrated design

Installations are organized logically to the structural and spatial design. Vertical installations and shafts are placed close to the elevator and stairways. Primary horizontal installations run along the middle beam, and secondary ones are placed between the LVL elements' ribs. The external load-bearing steel frame has a 1.8 meter grid and functions as a curtain wall, which means that tolerances were a crucial point of attention.

Non-traditional building process

One of the goals of the client of the project, cepezedprojects, was to achieve a short building time. Traditionally a building process consists of distinctive phases; first, completing the technical design and specifications and obtaining the building permit, followed by the tender phase, and lastly, the construction phase. For Building D, the client chose a highly integrated building team. The coordination of the building process was done by cepezedbouwteam and not by an external contractor. In this way, communication lines with the client and architect were kept extremely short. The pre-selection of project partners started during the final design and tender phases before requesting the building permit. This way of organization saved a lot of valuable time overall.

Fast building system

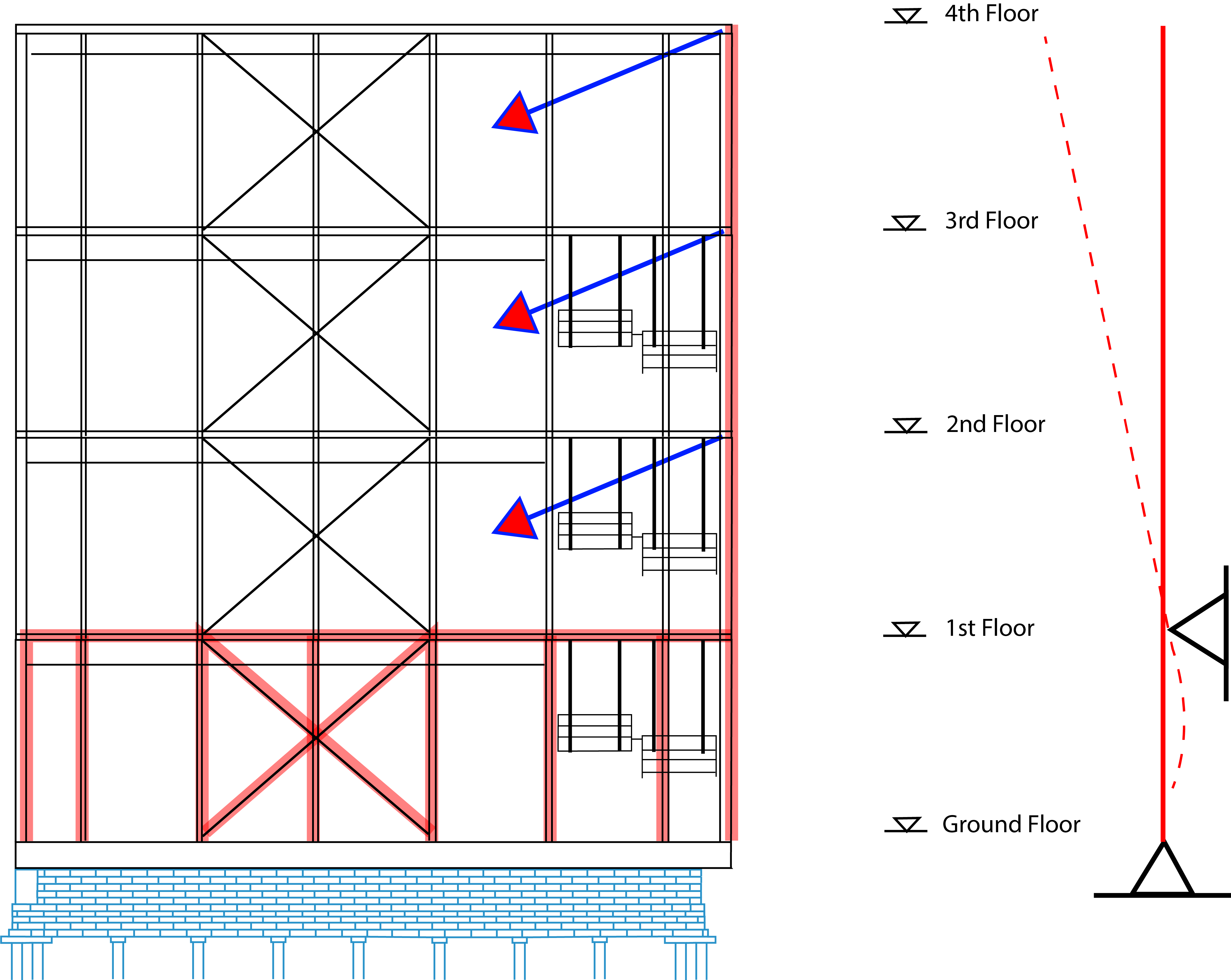

A design team consisting of cepezed and IMd Raadgevende Ingenieurs has developed smart connections between the steel structure and wooden floors – from sketch to drawing – to achieve a smart building system. The steel supplier has further elaborated on these details. The columns were designed to span the total building height to achieve a short building time. This meant that the highest point of the building was already reached on the first day of construction. The horizontal steel beams are placed in front of the columns. In two weeks, the entire steel structure was built. It took another two weeks to install all the wooden floors, see Figure 2. The glass facades were installed in the five following weeks, so in only nine weeks, the building envelope was closed entirely, see Figure 3.

Figure 2: Wooden floors installation

Fire safety

The total office area is just under 1000 m2, which means it can be considered as one fire compartment. The back facade is covered with a coating to prevent fire from spreading to the adjacent building and comply with the fire resistance requirements of 60 minutes. The same coating is applied to the steel structure on the ground floor, which keeps the back facade in place in case of fire, see Figure 4. It was not necessary to apply a (costly) coating on the steelwork of the higher floors. In case of fire, the weight of the collapsing upper floors could easily be carried by the first floor due to the lightweight construction, and the deformation of the cantilevered back facade would stay within limits.

Figure 3: Glass facades installation

The building has a very open and minimalistic character with structural elements in sight. To keep this image, fire-resistant cladding on the ceiling of the ground floor was undesirable. Instead, coated diagonal steel strips are placed over the wooden elements and under the compression layer of the first floor to comply with fire safety regulations

.

Figure 4: Fire safety principle

Final thoughts

With the realization of Building D, it has been demonstrated that using a suitable material in the right place can lead to a sustainable and future-proof building. By approaching the project as an integral design process, cepezed and IMd Raadgevende Ingenieurs, together with the installation advisor and steel supplier, have realized a smart building concept that can be built up just as fast as it can be demounted again.