The Petronas Twin Towers

Perhaps as important to Kuala Lumpur as the Eiffel Tower is to Paris and the Statue of Liberty is to New York; the iconic Petronas Twin Towers designed by Cesar Pelli are definitely the symbol of modern Malaysia. These two impressive towers were considered the tallest building in the world from 1998 to 2004. However, the towers are not simply recognized for their height: it was Pelli’s conceptual effort to incorporate Islamic motives and symbols into the design process that would influence the design and the detailing of the building. Furthermore, well known by the movie-experts among us, the Petronas towers were the film set of a 1999 movie called Entrapment, starring Catherine Zeta-Jones and Sean Connery. Even though I would really recommend this movie, this article gives you more information about the structural design and the construction of this impressive creature.

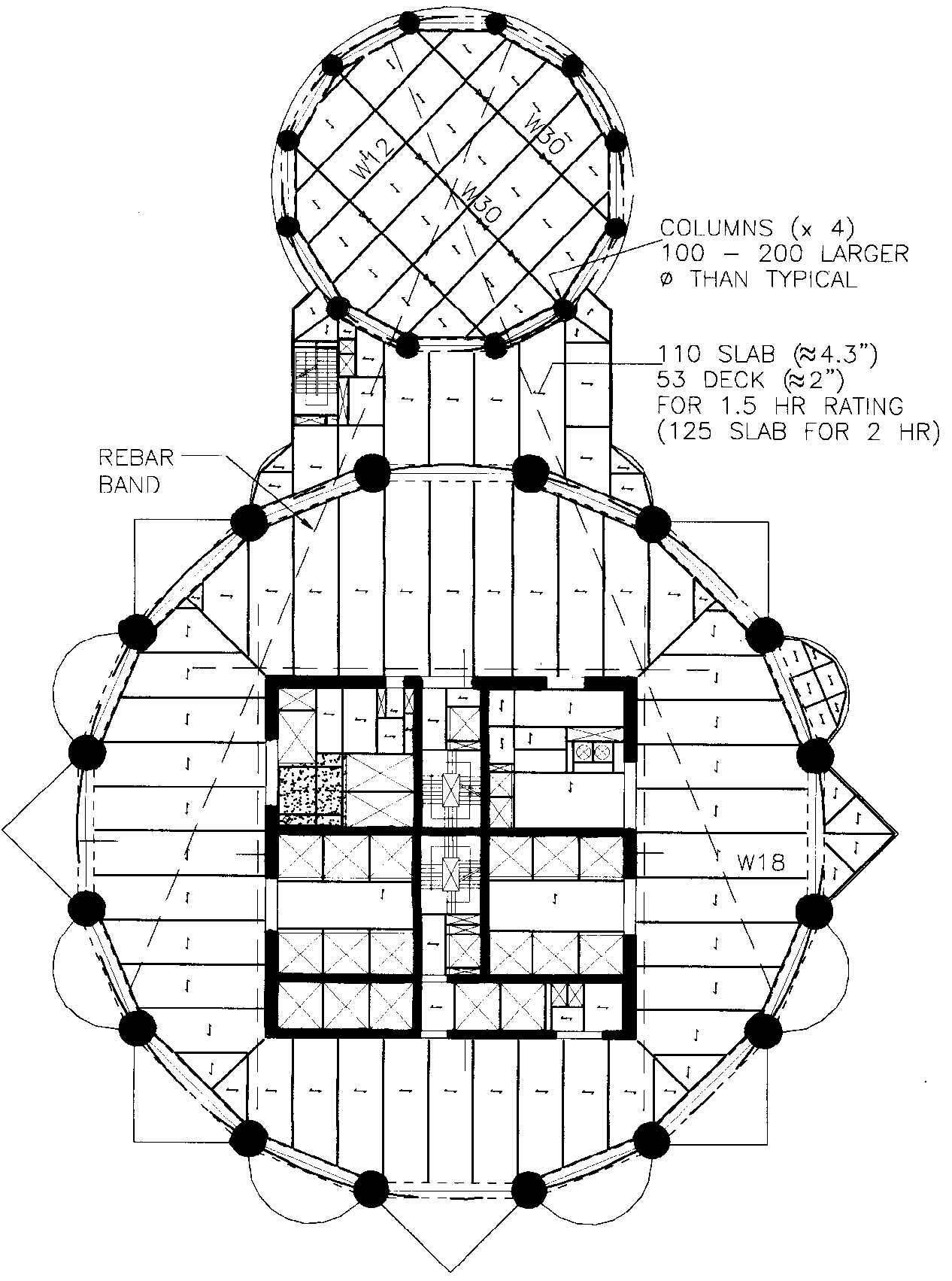

The Petronas Twin Towers, completed in 1998, each have approximately 21,800 square meters divided over 88 floors as part of the 1.7 million square meters Kuala Lumpur City Center mixed-use development. Their structures consist of high-strength concrete columns, core, and ring beams and also steel floor beams and decking to enable economic and fast construction. The slenderness of the towers and the Skybridge between them required attention to wind behaviour and damping, which will be explained later on.

A solid foundation

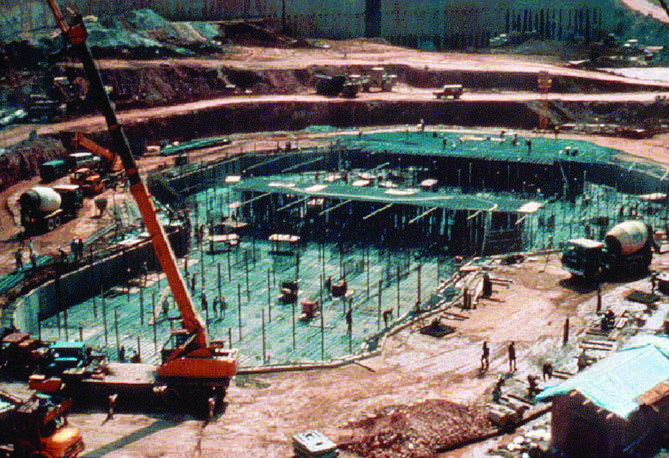

Excavation of the building pit started in March 1993, after developers shifted the whole site 60 meters to the southeast of where it was initially designed to be built. Drilling had shown bedrock irregularities at the site that would have made supporting the immense weight of the building an almost impossible challenge. With its newly fixed site a quick stroll away, a massive foundation was excavated, and its 21-meter depth was easily capable of swallowing a five-story building. During excavation, about 500 truckloads of soil were removed every night.

To support a single skyscraper with a weight of 300,000 metric tons is surely an impressive engineering feat, but

to pour a foundation that can handle two of such towers required not only a lot of structural knowledge, but also the largest and longest continuous concrete pour in Malaysian history – and this is a country that builds almost everything from reinforced concrete.

Each tower required an immense foundation, comprising a forest of deep piles driven into the bedrock; once the 104 concrete piles supporting each tower were driven into the earth, a 4.6-meter thick concrete raft was poured over them. For an impressive 54 hours, a truckload of concrete would arrive every 2.5 minutes to pour this massive foundation plate. From the beginning of the excavation until the completion of the massive foundation, one full year had passed. From that point on, the construction of the towers began.

Sky high

Originally, César Pelli had the towers topping out at 427 meters, which fell only 15 meters short of tying the current world’s tallest building: the Sears Tower in Chicago. Once Malaysia’s prime minister found out how close it was, he pressured the architects and engineers to find a way to make the towers taller so that the world’s tallest building would be in Malaysia.

Although the designers did not add any floors to the structure, they still found a way to push the height over 450 meters, wresting the crown from the United States for the first time since the construction of New York’s Empire State Building in 1931.

In yet another unorthodox decision: the construction of each separate tower was appointed to a different contractor. And, to make it even worse, both contractors were based in different countries. Japan-based Hazama Corporation led the consortium for Tower One, and South Korean titan Samsung Engineering and Construction led the build team for Tower Two plus the Skybridge: the unique two-level structure that would connect the two buildings at roughly their midpoints.

Figure 1: Construction of the massive foundation of Tower 1

Thousands of Malaysian and foreign workers were hired for the two construction teams… and the race was on! There was definitely a sense of competition to see which team would finish building their tower first, but also whose would be deemed best.

In the end, the competition for the best tower may have ended in a draw, but there is no question about who won on speed. The South Korean team had not only a tower but also a Skybridge to build and even started construction a month after the Japanese team. However, the Koreans did finish first, about a week before their rivals.

As the towers steadily reached ever upward, the stainless steel cladding was fitted to the facade, comprising 83,500 square meters of stainless steel extrusions and 55,000 square meters of laminated glass. This cladding was applied to realize Pelli’s vision of the Petronas Twin Towers being a ‘multi-faceted diamond sparkling in the sun.’

Dynamic studies

The dynamic properties of the main towers are important for cross-wind effects on the structure and for occupant comfort. The wind behaviour of the towers was studied in three ways.

Figure 2: Typical lower floor plan

Each tower was modelled in three dimensions using the SAP90 general analysis software, including perimeter beams and columns at all floors, a central column representing the core, and an outrigger beam system from columns to rigid offsets from the core.

Force balance wind model

A 1:400 high-frequency force balance model was used to determine along-wind and across-wind forcing functions for each overall tower. Based on the design wind speed of 35 m/s at 10 meters elevation, wind forces for structural design were determined from the mean and standard deviation of wind forces measured and the dynamic properties of the building.

Aeroelastic wind model

The highly articulated nature of the facade may cause helpful aerodynamic damping as the buildings move. The twin tower configuration may cause interaction between the towers through cyclic vortex shedding. Analytical procedures and force balance results are insufficient to study such phenomena. A 1:400 aeroelastic model of both towers hinged at their bases simulated along-wind and across-wind tower behavior, with critical damping being varied between one and three percent.

Notable dates

1993, March Start of the excavation.

1994, March Excavation and foundation for Tower One complete; construction begins.

1994, April Excavation and foundation for Tower Two complete; construction begins.

1995, May Pre-assembled Skybridge arrives from South Korea.

1995, August Skybridge is lifted into place.

1996, February Topping out of both towers is completed.

1996, March Installation of pinnacles for both towers.

1996, April Petronas Towers officially declared the world’s tallest building.

“A multi-faceted diamond sparkling in the sun.”

Results of tower studies

Aeroelastic values using two percent of critical damping showed slightly reduced base forces at one tower and slightly increased base forces at the other. Because even a slight increase in damping for ’50-year storm’ movements would reduce aeroelastic results, the design of both towers was based on the largest force-balance results for either tower. For occupant response, an inherent damping of 2 percent and a ’10 year storm’ gives peak accelerations at level 87 of 17 to 20 milli-g’s from force-balance tests and 14 to 18 milli-g’s from aeroelastic tests, well within the commonly used 21 milli-g’s guideline for comfortable office occupancy in long-period buildings. Therefore, supplementary dampings, such as viscoelastic pads or tuned mass dampers (TMDs), were needed or provided.

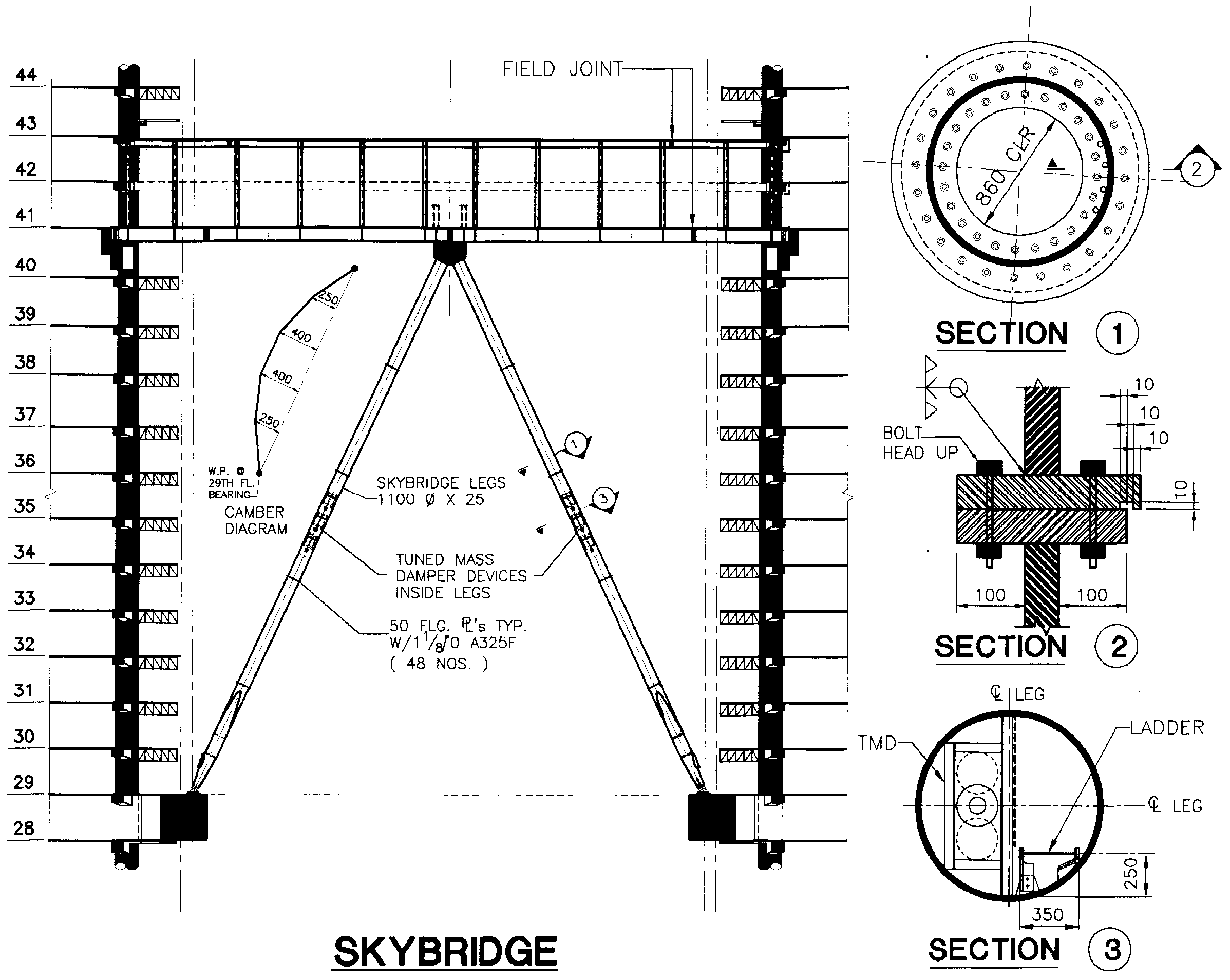

Figure 3: Skybridge elevation and details

The Sky bridge

The ultimate highlight of the Petronas Towers is the Skybridge, which connects the two buildings on their 41st and 42nd floor. This bridge holds the world record for the highest two-story bridge in the world and spans a distance of 58 meters. A complex system of hinges, expansion joints, and spherical bearings ensures that the Skybridge stays in place, regardless of how the two individual towers may independently move or twist.

A very demanding task was lifting the prefabricated Skybridge into its final place. Therefore, a specialized engineering firm was brought to manage the lift of the 450-ton assembly – including the 325-ton main structure as well as the support legs and other equipment - over 170 meters above the ground. The nine-step process took over a year to test and plan and two weeks to actually perform. In the end, it was flawlessly executed.

The response of long, slender, cylindrical bridge legs to vortex-shedding excitation at low wind speeds was of particular interest. Each leg is a steel tube with a diameter of 1.1 meters, spliced by butted bolted flanges. Pairs of legs diverge as they rise from a common lower support point on each tower. All four legs are effectively isolated from the rest of the bridge and the towers by joints of PTFE (teflon) on stainless steel: ball joints at lower bearings, ‘rocker’ and ‘slide’ bearings at box-to-girder support pad, and a ‘pin-in-globe’ bearing for lateral leg restraint at box midpoint.

Figure 4: The finishing touch of the Petronas Towers

The crowns

Finally, the time came to set the crowns on top of these twin towers. These crowns were gleaming 73.5 meters tall stainless pinnacles, which had been redesigned to bring the building’s official height to 451.9 meters above street level. From that moment in 1996, the Petronas Towers were the tallest building in the world until 2004, when the Taipei 101 took over the top spot, followed by the Burj Khalifa in 2010.

Interestingly, by the time Malaysia discovers whether or not it will achieve its stated goals in the year 2020. The Petronas Twin Towers will not even be in the top ten tallest buildings due to the rapidly advancing construction technologies. In fact, the expectation is that the Petronas Towers, once the tallest in the world, will rank at 27th place by 2020.

References

[1] Merchant, C. (2016). ‘The History and construction of the Petronas Twin Towers’ Available on December 3rd, 2016, Source: http://www.expatgo.com/my/2013/01/09/the-history-and-construction-of-the-petronas-twin-towers/

[2] Thornton C. H., Hungspruke U., Joseph L.M. (1997) ‘Design of the world’s tallest buildings – Petronas Twin Towers at Kuala Lumpur City Centre.’

Figures

Header, 1 and 5: Merchant, C. (2016). ‘The History and construction of the Petronas Twin Towers’ Available on December 3rd, 2016, Source: http://www.expatgo.com/my/2013/01/09/the-history-and-construction-of-the-petronas-twin-towers/

2-4: Thornton C. H., Hungspruke U., Joseph L.M. (1997) ‘Design of the world’s tallest buildings – Petronas Twin Towers at Kuala Lumpur City Centre’.