Structural Design of the Shanghai Tower

With a height of 632 meter, the Shanghai Tower is the tallest tower of China, the second tallest tower in the world, and a vertical city facilitating a variety of functions including office space, a luxury hotel, and an observation deck. The shape of the tower shows a beautiful integration between the architectural and structural design, in which a sophisticated structural design enables the creative architectural design. However, to be able to build the Shanghai Tower, several ingenious strategies were developed that are discussed in this article.

Origin and architectural design

The Shanghai Tower is located in the new financial center of Shanghai, China; an area that used to be farmland and has rapidly been transformed into a financial area over the last two decades (Figure 1). This transformation is spurred by Chinese economic reformations and required new planning and design strategies to address the need for high density development. Gensler, the responsible architect, incorporated the high-density development in the tower by means of a vertical city concept. For instance, sky gardens are created every 12 to 15 floors to create a sense of community. These sky gardens are located between the inner and outer skin of the building at the floors above the mega frames, which will be discussed later. The transparent outer skin forms the outer shape of the building and acts as a temperature buffer between outdoor and indoor. In fact, the entire tower is wrapped by this transparent second skin allowing the conservation of energy by modulating the temperature within the void: in the winter, cool air is heated up and in the summer, hot air is dissipated [3].

Figure 1: Transformation of Shanghai from 1991 (left) to 2016 (right)

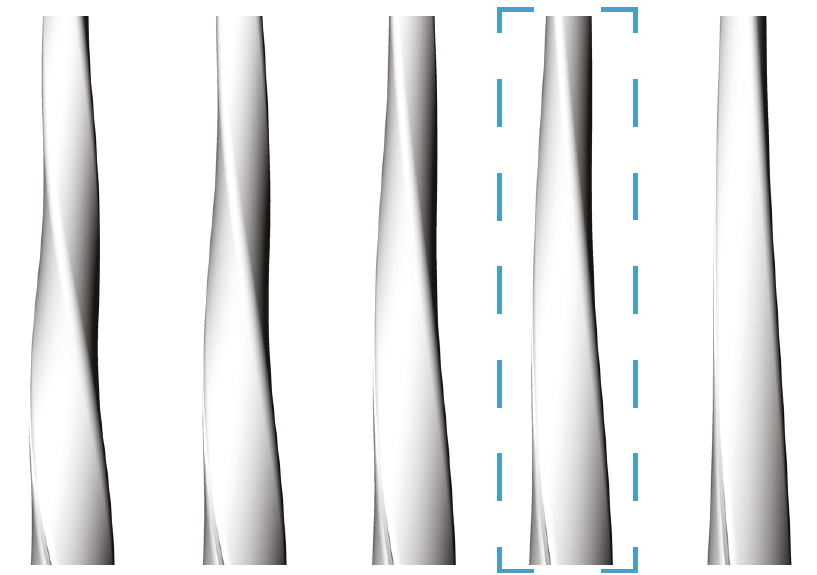

Figure 2: Aerodynamic design in the wind tunnel

The tower is exposed to typhoon-level wind loads and the shape of the tower is therefore designed in cooperation with the engineering firm Thornton Tomasetti, which made the complete structural design, as well as the aerodynamic design. To reduce the wind load on the building, the shape of the second skin is aerodynamically optimized in a wind tunnel (Figure 2) and with a computational fluid dynamics model. After testing multiple models, a rotation of 120 degrees between the bottom and upper plan was found to be the optimum (Figure 3). In addition, methods such as softening corners, tapering the shape along the elevation, adding setbacks, varying cross-sections, adding spoilers, and porosity in the building saved 58 million dollars of construction costs.

Figure 3: Plan rotation of 90° to 210° with the optimal shape of 120°

Structural Design

The structural design of the Shanghai Tower faced many challenges such as typhoon-level winds, an earthquake active zone, and a clay-based soil (river delta). The solutions that are found to overcome these challenges are listed in the rest of the article and divided by structural part or system.

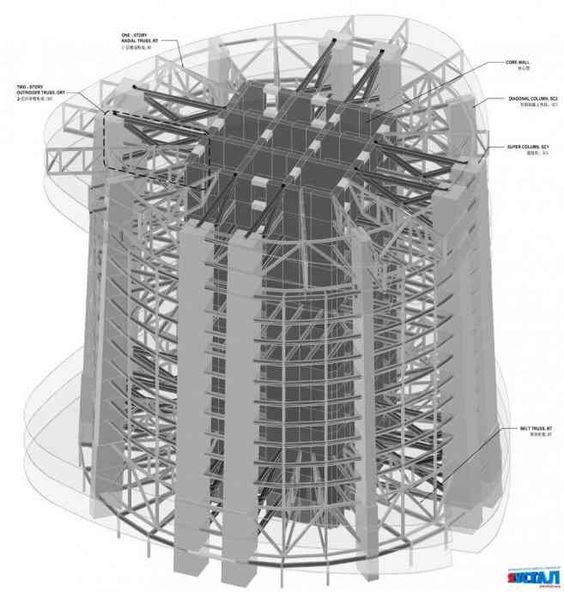

Stability and main construction

The structural parts of the tower that provide stability, and thus resistance against lateral and vertical forces, are a concrete core that interacts with outriggers and four paired super columns. The concrete core covers an area of nearly 30 square meters and forms the heart of the structural system. To facilitate outrigger connections and to resist extreme bending moments, the concrete core had to be partly reinforced with steel beams and plates in addition to traditional reinforcement. This composite reinforcement method is frequently used in high-rise and especially in super-high-rise buildings.

The super columns are composed of specially designed steel profiles that are covered and filled with concrete to increase the fire resistance and mechanical strength. All beam to super column connections are encased in concrete as well to ensure a proper and stiff performance of the complete structure. The four paired super columns are placed at each 45-degree axis and partly support the outriggers. To decrease the span between these columns near the base, four additional super columns are added to reduce the span from 50 meters to 25 meters (Figure 4).

Figure 4: Structural system with all super columns and mega frame under construction near the base of the tower

In addition, a two floor tall mega frame is added between all the super columns every 12 to 15 floors, which divides the tower into nine zones. At the interface of the adjacent zones, space is created for refuge safety areas and mechanical plus electrical plumbing equipment. These floors, located between and on top of the mega frames, span from outer to inner skin and support the vertical weight of 12 to 15 floors of facade. The main task of the mega frames is to provide lateral resistance in combination with the core, outriggers, and super column system. Furthermore, intermediate steel columns are supported by the mega frame. The mega frame is constructed as a double belt truss of structural steel.

The stresses in most of the structural members are in the elastic range; however, the link beams in the core wall exhibit fully plastic deformations but do not exceed the limits set by China’s building code.

Software and earthquake resistance

Since the site of the tower is located in an earthquake active zone, the non-linear (plastic) structural behavior, especially the behavior of connections of the main joints, had to be determined. The finite element program Abaqus was used to perform the tests on the (composite) three-dimensional elements and to prove that the structure is able to withstand extreme dynamic loads and meet China’s Seismic Design Code.

Both steel and concrete elements of the composite structures were modeled in Abaqus. The steel elements were modeled as beam elements and the concrete elements as shell elements. Since M-N-θ (moment, axial force, and rotation) profiles could be determined from the Abaqus models and the soil conditions were known, the total lateral deformation of the tower could be determined.

Foundation and lateral deformations

The site of the Shanghai Tower is located in a former river delta with a clay type soil in the upper layers. This results in foundation bore piles with a diameter of 1 meter and alength of 52 to 56 meter to be able to reach the bedrock. A 6-meter-deep foundation slab connects the 947 bore piles to the tower. This results in a stiff foundation, by which the total horizontal deformations (drift ratio) of the tower are in either axis less than 1/130 in any direction. This meets the limit of 1/100 specified in China’s Building Code.

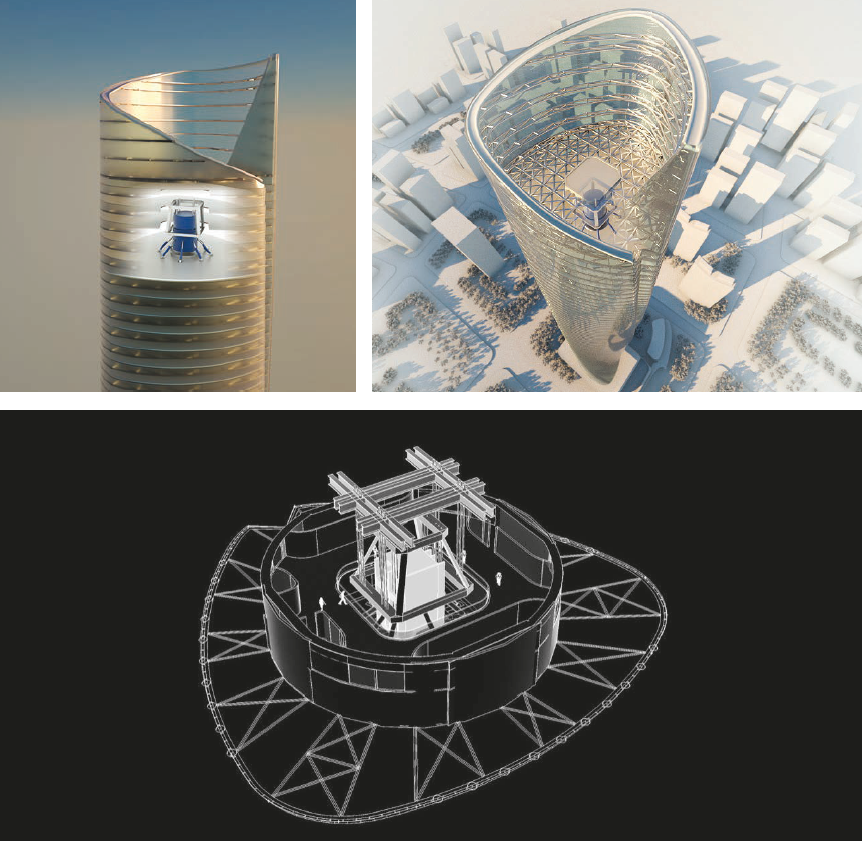

However, to reduce the deformation of the tower at the top and to improve the comfort of inhabitants, a 1,000 ton mass damper is added in the top of the tower. This damper acts as counterweight by ‘pulling’ the tower in the opposite direction when the building sways (Figure 5). A so called Eddy-current damper is used to stabilize the weight. This damper uses magnets to provide active damping control. These dampers are easily adjustable when vibration frequencies change. The iron weight induces an electrical current in the damper that, in turn, creates an opposite magnetic field and automatically counteracts the weight’s motion and further amplifies the damping effect.

The Shanghai Tower is the first skyscraper in the world that uses Eddy-current dampers. Air sickness of inhabitants will be prevented with this mass damper.

Figure 5: 1,000 ton mass damper tuned by means of Eddy-current dampers

The outer skin

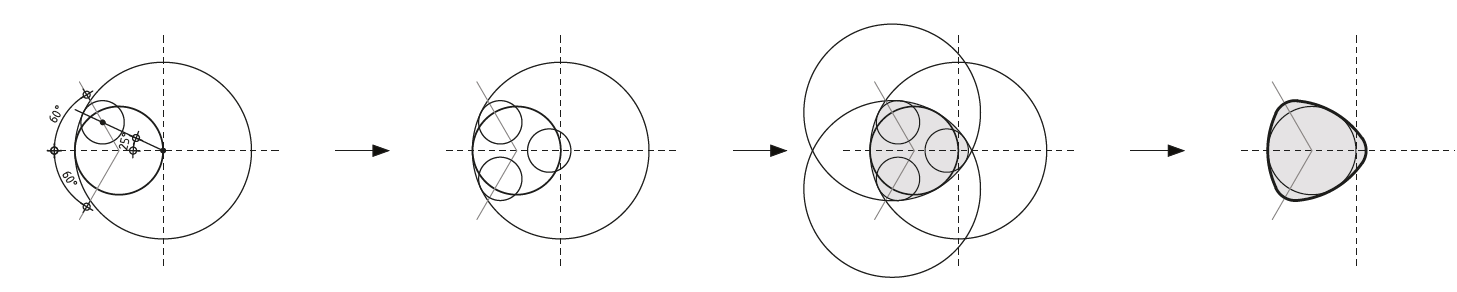

The cam-shaped outer skin is comparable to the shape of a guitar pick (Figure 6) and decreases wind loads on the

main structure as mentioned before. Nevertheless, the skin of the tower is sometimes exposed to typhoon-level wind loads. These loads have to be transferred via the space between the first and second skin, which requires additional structures.

Figure 6: Geometric design and concept of the towers’ external shape

Non-sway compression or tension bars are attached to special joints and bridge the space between the inner and outer skin to transfer the wind loads to the stability system of the tower (Figure 7). Special joints between these bars must allow for different temperature deflections, which is possible by means of ‘flexible’ expansion joints that are designed to cover both functions. The structure of the outer skin is created by cam-shaped hoop rings that taper and rotate 120 degrees from the bottom to the top of the tower creating the unique and aerodynamically height accenting shape.

Conclusion

The iconic shape of the tower anchors the tower as Shanghai’s landmark and represents a new era of creating

vertical cities. Cutting edge developments in technology have helped the designers to face the tremendous design

challenges and have let them explore the boundaries of super-high-rise design. With the Shanghai Tower, Shanghai’s

financial area is becoming one of the world’s foremost commerce destination; however, the tower is not yet completely open at the time of writing.

Figure 7: Atrium between inner and outer skin

The tower today

The construction of the tower began in November 2008, after which the observation deck on the 121st floor opened in July 2016. At the time of writing this article, most stories of the Shanghai Tower are closed. It is unknown when the complete tower is scheduled to open, but a fact is that the Shanghai Tower is a soaring symbol of China’s economic future.

Figure 8: The tower section, construction, and skin during/after construction

--- Shanghai Tower facts ---

Architect: Gensler

Structural engineer: Thornton Tomasetti

General

• With a height of 632 meters, the Shanghai Tower is the tallest tower in China and at the time of writing the second tallest tower in the world.

• The floor space covers 380,000 square meters spread over 124 floors (above grade).

• 14 percent less glass was needed for the skin compared to a square building with the same floor space.

• Afforded by modern digital technology, mass customization allowed the production of 7,000+ unique glass skin panels on a total of 20,589.

• The elevators in the building can reach speeds up to 64.8 km/h.

• The program of the tower facilitates office space, a luxury hotel, entertainment, retail, and cultural venues.

• The construction costs are 2.2 billion dollars.

Green strategies

• The tower has its own power facility providing heat and electricity to the low zone areas.

• External light of the tower is powered by 270 wind turbines, built into the facade.

• The double facade provides an insulating blanket for the tower, which saves energy.

• Water treatment plants are added in the tower to recycle grey and storm water for irrigation and toilet flushing, resulting in reducing 38 percent of water consumption. The plants are located at efficient places, by which pumping energy is reduced.

• The energy required for transporting energy is significant in super-high-rise buildings. By means of the vertical city concept, the nine stacked 12 to 15 story buildings are served by a central utility infrastructure, which allows for substantial reduction in energy transportation.

• 21 percent of the total energy use is saved by 43 sustainable technologies.

Structural

• The foundation slab of the tower has a depth of 6 meters and was poured during a 63 hour pour, in which 61,000 cubic meters of concrete was pumped.

• The 120-degree turn from base to top saved 58 million dollars of structural costs due to the decreased wind load on the structure.

• A tuned mass damper of 1,000,000 kilograms, which is placed near the top of the tower, improves the comfort of occupants by means of reducing the sway.

About the structural engineer

Shanghai Towers’ engineer Thornton Tomasetti provides engineering design, investigation, and analysis services to clients worldwide on projects of every size and level of complexity. Projects include the structural design of (super) high-rise structures, stadiums, innovative structures, and structural forensics of collapses. Thornton Tomasetti is an independent, employee-owned firm of 1,200 engineers, architects, sustainability practitioners, and supports professionals collaborating from offices across North America and in Asia-Pacific, Europe, Latin America, and the

Middle East (Thornton Tomasetti, 2016).

References:

[1] Xia, J., Poon, D., Mass D. C. (2010). Case Study: Shanghai Tower. CTBUH Journal.

[2] Zhao, X., Ding, J. M., Sun H. H. (2011). Structural Design of Shanghai Tower for Wind Loads. Architectural design & research institute of Tongji university (Group) Co., Ltd., 200092, Shanghai, China

[3] http://www.thorntontomasetti.com/about/

[4] Gensler/Shen Zhonghai, Blackstation, Courtesy of Arch Record

[5] http://www.autodesk.com/gallery/exhibits/currently-on-display/shanghai-tower

[6] http://www.slideshare.net/SanskritiJindal/shanghaitower-40930153